Posted on April 13, 2024

What are the Steps in Circuit Breaker Testing?

Kind Tests of circuit breaker

Type examinations are organised with the goal of confirming the capacities and making certain the rated particular of the circuit breaker are exact. Such tests are conducted in the specially built testing research laboratory.

Mechanical Examination– It is mechanical capacity type test entailing the duplicated opening and closing of the breaker. A circuit breaker should close and open at proper rate and do its assigned task and function without any failure.

Thermal Examination– Thermal tests are executed to check the thermal actions of the circuit breakers. As a result of the streaming of rated existing via its pole in a rated problem, the breaker under test undertakes steady-state temperature level increases. The temperature increase for ranked existing ought to not go beyond 40 ° for current less than 800A typical current and 50 ° for typical value of current 800A and above.

Dielectric Examination– These examinations are executed to examine power frequency and impulse voltage hold up against capacity. Power regularity tests are kept on a new circuit breaker; the examination voltage modifications with a breaker rated voltage. In impulse tests, impulse voltage of certain value is utilized to the breaker. For outdoor circuit dry and damp examinations are conducted.

Brief -Circuit Examination– Breaker are subjected to unexpected short-circuits in short-circuit test research laboratories, and oscillograms are taken to recognize the behavior of the circuit breakers at the time of switching in, throughout get in touch with splitting and after the arc extinction. The oscillograms are researched with certain referral to the production and damaging currents, both balanced and asymmetrical restriking voltages, and switchgear is in some cases checked at rated conditions.

Regular Examinations of a Breaker

Routine tests are done as per recommendations of standards of Indian Engineering Solution and Indian Standards. These examinations are done on the manufacturers’ premises. Regular examinations verify the proper functioning of the circuit breaker. The routine examinations confirm the correct performance of the breaker. Routine screening does not always include complicated gear in order to ensure that a circuit breaker is functional. Some guidelines and suggestions for these tests consist of routine maintenance and verifying that breaker efficiency remains in line with manufacture’s calibration contours. It is important that these examinations are done under stable problems at appropriate temperature so that there are no variants in the information. A few of the examinations are listed here.

Breaker Journey Examination

By evaluating the current eaten by the trip coil during the circuit breaker’s procedure, it is feasible to figure out whether there are mechanical or electrical concerns present. Oftentimes, such concerns can be localised to assist in finding the origin. Optionally, keeping an eye on the stumbling supply’s voltage during the operation can discover problems occurring with stumbling batteries.

Insulation Resistance Test

For private breaker resistance testing, load and line conductors should be preferably disconnected. If not separated the examination worths will certainly likewise include the qualities of the linked circuit. Resistance testing is vital for verifying that the shielding product which makes up the molded situations breakers are carrying out properly. In order to check for insulation resistance, an instrument called a megger is made use of. A megger instrument applies a known DC voltage to an offered cable for a given amount of time in order to test the resistance within the insulation on that certain cable or winding. It is important that voltage is utilized as the resistance consulted an ohmmeter might vary when there are no record of possible differences. It must also be noted that if you apply a voltage that is expensive for that insulation to withstand, then you can possibly damage the insulation.

Connection Examinations

Connection screening is very important to make certain that an ideal electric connection is available and to recognise traces of overheating represented by colour difference. It is necessary that electrical links are correctly installed to the CB to avoid and minimize overheating.

Get In Touch With Resistance Examination

Typical deterioration of calls within the CB emerges after expanded use. A simple technique to determine traces of deteriorating within the circuit breaker is to quantify the resistance across every pole of the breaker. Indicators of unusual problems within the CB such as erosion and contamination of contacts appear if there are extreme millivolt drops throughout the breaker. The call resistance test is very important in discovering if or not a breaker is still apt for functioning.

Overload Tripping Test

Overload stumbling parts of CBs can be checked by inputting 300% of the breaker score into each pole of the circuit breaker to determine that it will open up automatically. The intention of this is to make sure that the circuit breaker will run or otherwise. Describe NETA standards for trip times that serve for the overload stumbling examination. When looking for out tripping qualities, it is advisable to seek advice from maker’s guidebooks.

Instantaneous Magnetic Tripping

In regular examinations, it pertains to discover that the magnetic feature is practical and will trip the circuit breaker instead of locating the precise value at which the instant magnetic function functions.

Posted on March 1, 2024

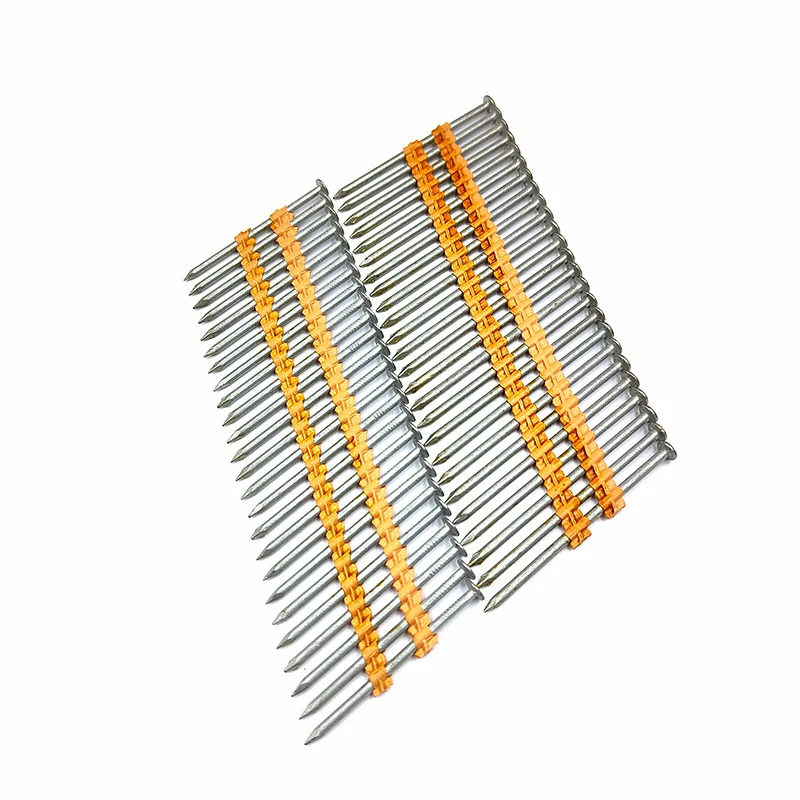

How do 21-degree plastic collated nails perform in terms of resistance to fatigue or cyclic loading?

The performance of 21-degree plastic collated nails in terms of resistance to fatigue or cyclic loading depends on various factors including the material composition, length, diameter, and installation method.

Here’s how they typically perform:

- Material Composition: 21-degree plastic collated nails are usually made from high-strength steel, providing good resistance to fatigue and cyclic loading. The material’s ability to withstand repeated stress without permanent deformation or failure contributes to its durability under cyclic loading conditions.

- Length and Diameter: Longer and thicker nails generally offer greater resistance to fatigue and cyclic loading due to their increased cross-sectional area and embedment depth. They can distribute applied loads more effectively, reducing the risk of nail bending or breakage during cyclic loading cycles.

- Installation Method: Proper installation techniques, such as driving the nails perpendicular to the workpiece and ensuring adequate penetration depth, are essential for maximizing the resistance to fatigue and cyclic loading. Improperly driven nails may experience premature failure due to increased stress concentrations or inadequate anchorage.

- Environmental Factors: Environmental conditions, such as exposure to moisture, temperature variations, and corrosive substances,21 degree plastic collated nails can affect the fatigue resistance of 21-degree plastic collated nails. Corrosion-resistant coatings or materials can help mitigate the detrimental effects of environmental factors on nail performance.

- Design Considerations: The design of the nail head and shank can also influence its resistance to fatigue and cyclic loading. Features such as a tapered shank or textured surface may enhance the nail’s ability to maintain grip and resist loosening or withdrawal forces during cyclic loading cycles.

Overall, 21-degree plastic collated nails generally exhibit good resistance to fatigue and cyclic loading when properly selected, installed, and maintained. However, it’s essential to consider the specific application requirements and environmental conditions to ensure optimal performance and durability over time. Regular inspection and maintenance can help identify any signs of fatigue or degradation and address them promptly to prevent potential issues.

Posted on March 1, 2024

How does the wafer type check valve pressure surges?

The wafer type check valve helps mitigate pressure surges in a piping system through its unique design and operational characteristics:

- Quick Response: Wafer type check valves are designed to respond rapidly to changes in flow direction or pressure within the pipeline. When a pressure surge occurs, such as a sudden increase in flow velocity or a water hammer effect, the check valve quickly closes to prevent reverse flow, thereby reducing the impact of the surge.

- Non-Slam Design: Many wafer type check valves feature a non-slam design, which means they close smoothly and quietly without producing a loud slamming noise. This design minimizes the shock waves generated by the closure of the valve, helping to dampen pressure surges and prevent damage to downstream equipment.

- Spring-Assisted Closure: Some wafer type check valves are equipped with spring-loaded discs or pistons that provide additional force to ensure prompt closure of the valve when reverse flow conditions are detected. wafer check valve manufacturer china This spring-assisted closure helps maintain tight sealing and effectively control pressure surges.

- Low Head Loss: Wafer type check valves typically have a streamlined flow path and low pressure drop, which means they introduce minimal resistance to flow during normal operation. This characteristic helps to minimize the buildup of pressure within the pipeline and reduces the intensity of pressure surges.

- Proper Sizing and Installation: Correctly sizing and installing wafer type check valves in the piping system is crucial for effective surge protection. Ensuring that the valves are sized appropriately for the flow rates and pressures in the system, and installed in accordance with manufacturer guidelines, helps optimize their performance in mitigating pressure surges.

- Regular Maintenance: Routine inspection and maintenance of wafer type check valves are essential for ensuring their continued effectiveness in controlling pressure surges. Checking for signs of wear, corrosion, or damage, and promptly addressing any issues, helps maintain the integrity and reliability of the valves over time.

By incorporating these features and considerations, wafer type check valves play a vital role in managing pressure surges within piping systems, helping to protect equipment, prevent leaks, and maintain system integrity.

How does the wafer type check valve facilitate easy access for maintenance?

Wafer type check valves are designed to facilitate easy access for maintenance through several key features:

- Compact Design: Wafer type check valves have a compact and lightweight design, making them easy to handle and maneuver during installation and maintenance procedures. Their streamlined profile allows for convenient access to the valve and surrounding equipment.

- Wafer Body: The wafer body design of these check valves enables them to be installed directly between flanges in the pipeline, without the need for additional mounting hardware or space-consuming components. This simplifies installation and allows for easy removal and reinstallation during maintenance activities.

- Split-Body Construction: Some wafer type check valves feature a split-body construction, allowing the valve to be disassembled into separate halves for maintenance or repair purposes. This design facilitates easy access to internal components, such as the disc, seat, and spring, without the need to disconnect the valve from the pipeline.

- Bolted Bonnet or Cover: Wafer type check valves may incorporate a bolted bonnet or cover mechanism that provides secure sealing while also allowing for straightforward removal for maintenance. By loosening the bolts, wafer type check valve technicians can quickly access the internals of the valve for inspection, cleaning, or replacement of parts.

- Integrated Access Ports: Some wafer type check valves are equipped with integrated access ports or inspection windows that provide visibility into the valve interior without requiring disassembly. These access points allow technicians to visually inspect the condition of internal components and identify any issues that may require attention.

- Standardized Components: Many wafer type check valves use standardized components and assembly techniques, making it easier to source replacement parts and perform maintenance tasks. This simplifies the maintenance process and reduces downtime associated with servicing the valves.

- Clear Markings and Documentation: Manufacturers often provide clear markings, labels, and documentation to aid in the identification and maintenance of wafer type check valves. This includes information on valve specifications, installation instructions, and recommended maintenance procedures, helping technicians perform tasks efficiently and accurately.

Overall, the design features of wafer type check valves are geared towards ensuring easy access for maintenance, allowing technicians to quickly inspect, service, and repair the valves as needed to maintain optimal performance and reliability in the piping system.

Posted on February 22, 2024

How are workforce training and skills development addressed to ensure proficient operation and maintenance of baby wipes raw materials?

Workforce training and skills development are essential to ensure proficient operation and maintenance of baby wipes raw materials.

Here’s how manufacturers typically address this:

- Comprehensive Training Programs: Manufacturers develop comprehensive training programs to educate employees on the handling, storage, and processing of raw materials used in baby wipes production. These programs cover topics such as material properties, safety protocols, equipment operation, quality standards, and maintenance procedures.

- Onboarding and Orientation: New employees undergo onboarding and orientation sessions to familiarize them with the company’s processes, procedures, and safety guidelines related to raw material handling. This includes introductions to workplace hazards, emergency protocols, and proper handling techniques to ensure safe and efficient operation.

- Hands-On Training: Hands-on training is provided to employees to develop practical skills in raw material handling and processing. This may involve supervised practice sessions where employees learn to operate equipment, handle materials safely, troubleshoot common issues, and perform routine maintenance tasks under the guidance of experienced trainers.

- Cross-Training and Skill Development: Manufacturers encourage cross-training and skill development among employees to enhance versatility and flexibility in raw material handling operations. This includes providing opportunities for employees to learn different roles, acquire new skills, and gain proficiency in multiple aspects of raw material processing.

- Continuous Education and Learning: Manufacturers promote a culture of continuous education and learning by offering ongoing training and development opportunities to employees. This may include workshops, seminars, online courses, and certifications related to raw material handling, safety practices, equipment operation, baby wipes raw materials and industry best practices.

- Safety Training and Compliance: Safety training is a top priority to ensure that employees understand the potential hazards associated with raw materials used in baby wipes production and how to mitigate risks effectively. Manufacturers conduct regular safety training sessions, provide personal protective equipment (PPE), and reinforce safe work practices to prevent accidents and injuries.

- Quality Assurance Training: Quality assurance training is provided to employees to ensure that they understand the importance of maintaining product quality and consistency throughout the manufacturing process. This includes training on quality control procedures, product specifications, sampling techniques, and defect detection methods to identify and address issues promptly.

- Equipment Maintenance Training: Proper maintenance of equipment used in raw material handling is crucial to ensure reliable operation and minimize downtime. Manufacturers provide training on equipment maintenance procedures, including routine inspections, lubrication, calibration, and troubleshooting techniques, to empower employees to perform preventive maintenance and address minor issues proactively.

- Performance Monitoring and Feedback: Manufacturers monitor employee performance and provide constructive feedback to identify areas for improvement and recognize achievements. Regular performance evaluations, feedback sessions, and coaching opportunities help employees refine their skills, overcome challenges, and contribute effectively to raw material handling operations.

- Empowerment and Engagement: Manufacturers empower employees by fostering a culture of empowerment, accountability, and continuous improvement. By involving employees in decision-making processes, encouraging feedback, and recognizing their contributions, manufacturers create a supportive and engaging work environment where employees feel valued and motivated to excel in their roles.

Posted on February 22, 2024

What are the trends and innovations shaping the future of wet wipes manufacturing?

Several trends and innovations are shaping the future of wet wipes manufacturing, driven by evolving consumer preferences, technological advancements, and sustainability considerations.

Some of the key trends and innovations include:

- Biodegradable and Sustainable Materials: There is a growing demand for wet wipes made from biodegradable and sustainable materials to reduce environmental impact. Manufacturers are exploring alternative fibers, such as bamboo, cotton, and plant-based cellulose, as well as eco-friendly packaging options to meet this demand.

- Flushable and Dispersible Wipes: Flushable and dispersible wipes that break down quickly and safely in sewer systems are gaining popularity. Manufacturers are developing innovative formulations and manufacturing processes to produce wipes that meet flushability standards while maintaining performance and durability.

- Natural and Organic Formulations: Consumers are increasingly seeking natural and organic wet wipes made with gentle, non-toxic ingredients. Manufacturers are responding by formulating wipes with natural extracts, botanicals, and organic oils, free from harsh chemicals, fragrances, and preservatives.

- Antimicrobial and Disinfecting Wipes: The demand for antimicrobial and disinfecting wipes has surged in response to health and hygiene concerns, particularly in light of global pandemics. Manufacturers are developing wipes with effective antimicrobial agents, such as alcohol, hydrogen peroxide, or quaternary ammonium compounds, to provide sanitizing and disinfecting properties.

- Customization and Personalization: There is a growing trend towards customized and personalized wet wipes tailored to specific consumer preferences and needs. Manufacturers are offering customizable options in terms of scent, texture, size, and packaging to cater to diverse market segments and niche applications.

- Smart Wipes and IoT Integration: Advancements in smart technology and Internet of Things (IoT) integration are enabling the development of smart wipes with interactive features and functionalities. Manufacturers are exploring opportunities to incorporate sensors, wet wipes manufacturing QR codes, or RFID tags into wipes packaging for enhanced tracking, authentication, and user engagement.

- Single-Use Packaging and Portability: Convenience and portability continue to drive demand for single-use wet wipes packaged for on-the-go use. Manufacturers are innovating with compact and travel-friendly packaging formats, such as pouches, sachets, and individually wrapped wipes, to cater to busy lifestyles and mobile consumers.

- Multi-Functional Wipes: Multi-functional wipes that serve multiple purposes, such as cleansing, moisturizing, and sanitizing, are gaining popularity. Manufacturers are developing hybrid formulations and designs to deliver versatile performance and address diverse consumer needs with a single product.

- Hybrid and Sustainable Manufacturing Processes: Manufacturers are adopting hybrid manufacturing processes that combine traditional and sustainable methods to optimize efficiency and reduce environmental impact. This includes integrating renewable energy sources, water recycling systems, and waste minimization strategies into wet wipes production facilities.

- Regulatory Compliance and Standards: Compliance with stringent regulatory requirements and industry standards remains a key focus for wet wipes manufacturers. Continued adherence to safety, quality, and environmental regulations is essential to ensure consumer confidence and market acceptance of wet wipe products.

Overall, the future of wet wipes manufacturing is characterized by innovation, sustainability, customization, and technological advancements aimed at meeting evolving consumer needs and expectations while addressing environmental concerns and regulatory requirements.

Posted on February 6, 2024

How are pneumatic actuator butterfly valve employed in water treatment plants for industrial applications?

Pneumatic actuator butterfly valves are commonly employed in water treatment plants for various industrial applications due to their reliability, quick response, and ability to control fluid flow effectively.

Here are several ways in which pneumatic actuator butterfly valves are utilized in water treatment plants:

- Flow Control in Pipelines:

- Pneumatic actuator butterfly valves are used to control the flow of water in pipelines within water treatment plants. They can be positioned to regulate the volume of water passing through, ensuring optimal flow rates for different stages of the treatment process.

- Isolation and Shut-Off:

- These valves are employed for isolating sections of the pipeline during maintenance or emergencies. Their quick-acting nature allows for swift shut-off, minimizing the impact of unexpected events and facilitating maintenance activities without disrupting the entire system.

- Water Treatment Processes:

- Pneumatic actuator butterfly valves play a crucial role in various water treatment processes, such as sedimentation, filtration, and chemical dosing. By controlling the flow of water and chemicals at different stages, these valves contribute to the efficiency and effectiveness of the treatment process.

- Backflow Prevention:

- Butterfly valves with pneumatic actuators are utilized to prevent backflow in water treatment systems. Backflow can introduce contaminants into clean water supplies, and these valves help maintain the direction of flow, ensuring water quality standards are met.

- Tank and Reservoir Control:

- Pneumatic actuator butterfly valves are installed in tanks and reservoirs to control the filling and emptying processes. This ensures precise water level management and helps maintain optimal conditions for treatment and distribution.

- Chemical Injection:

- In water treatment plants, various chemicals are often added to adjust pH levels, disinfect water, or aid in coagulation and flocculation.pneumatic actuator butterfly valve Pneumatic actuator butterfly valves are used to control the injection of these chemicals into the water streams, ensuring accurate dosing.

- Emergency Response:

- Pneumatic actuator butterfly valves are crucial in emergency response situations, allowing for quick isolation of specific sections of the water treatment system to contain issues such as leaks, contamination, or equipment failures.

- Integration with Control Systems:

- These valves can be integrated into the overall control and automation systems of water treatment plants. Pneumatic actuators facilitate remote control and monitoring, enabling operators to make real-time adjustments based on process conditions and optimizing overall plant performance.

- Durability and Corrosion Resistance:

- Butterfly valves with pneumatic actuators are often chosen for their durability and resistance to corrosion, which is particularly important in the corrosive environments commonly found in water treatment plants.

- Energy Efficiency:

- Pneumatic actuators offer efficient energy usage, as they require less power for operation compared to some other actuation methods. This contributes to the overall energy efficiency of water treatment processes.

In summary, pneumatic actuator butterfly valves are versatile components in water treatment plants, contributing to flow control, isolation, chemical dosing, and overall system reliability. Their quick response, reliability, and adaptability make them well-suited for the dynamic and critical processes involved in treating and distributing water for industrial applications.

Posted on February 6, 2024

How do electrically actuated valves contribute to energy efficiency in industrial automation?

Electrically actuated valves play a crucial role in enhancing energy efficiency in industrial automation by offering precise control, rapid response, and the ability to integrate seamlessly into automated systems.

Here are several ways in which electrically actuated valves contribute to energy efficiency:

- Precision Control: Electric actuators provide precise control over the valve position, allowing for accurate regulation of fluid flow rates and pressure levels. This precision helps optimize the overall process, ensuring that the system operates at its most efficient point.

- Variable Flow Control: Electric actuators enable variable and modulating control of the valve position, allowing for adjustments to meet changing process conditions. This flexibility helps match the actual demand, preventing unnecessary energy consumption during periods of lower demand.

- Energy Savings in Partial Load Conditions: Electric actuators can efficiently operate at partial load conditions, adjusting the valve opening to meet the specific requirements of the system. This capability is especially important in processes with varying loads, as it prevents the need to run the system at full capacity when not necessary.

- Remote Monitoring and Control: Electrically actuated valves can be integrated into industrial control systems, enabling remote monitoring and control. This feature allows operators to make real-time adjustments based on process conditions, optimizing energy usage without the need for physical presence at the valve site.

- Quick Response Time: Electric actuators have faster response times compared to some other types of actuators. This quick response allows for rapid adjustments to changing conditions, minimizing energy waste during transient states and ensuring the system operates at optimal efficiency.

- Position Feedback and Closed-Loop Control: Electric actuators often incorporate position feedback devices, such as sensors, china valve supplier to provide real-time information on the valve’s position. This information can be used in closed-loop control systems to maintain precise valve positions, reducing energy losses associated with overshooting or undershooting the desired setpoint.

- Integration with Energy Management Systems: Electrically actuated valves can be seamlessly integrated into broader energy management systems. By incorporating them into a comprehensive control strategy, industrial facilities can optimize energy usage across multiple processes and equipment.

- Reduced Maintenance Downtime: Electric actuators generally require less maintenance compared to some other types of actuators. Reduced downtime for maintenance means that the system can operate continuously, avoiding unnecessary starts and stops that can be less energy-efficient.

- Adaptability to Renewable Energy Sources: In facilities where renewable energy sources are employed, electric actuators can easily adapt to changes in power sources. This adaptability allows for better alignment with the availability of renewable energy, further enhancing the overall energy efficiency of the industrial process.

In summary, electrically actuated valves contribute to energy efficiency in industrial automation by providing precise control, adaptability to varying conditions, and integration capabilities with advanced control systems, ultimately helping industrial processes operate more efficiently and sustainably.

Posted on January 29, 2024

How is the compatibility of kraft stand up pouch materials with various pet food formulations ensured?

Ensuring the compatibility of kraft stand-up pouch materials with various pet food formulations involves careful consideration of both the packaging material properties and the specific characteristics of the pet food.

Here are key steps and considerations to ensure compatibility:

- Material Selection:

- Choose kraft stand-up pouch materials that are suitable for direct contact with pet food. The materials should be food-grade, compliant with relevant regulations, and have the necessary barrier properties to protect the contents from external factors.

- Barrier Properties:

- Assess the required barrier properties based on the specific pet food formulation. Consider factors such as moisture resistance, oxygen barrier, and protection against odors. The chosen kraft material should provide the necessary protection to maintain the quality and freshness of the pet food.

- Lamination or Coating:

- Depending on the pet food formulation, consider whether additional layers, coatings, or laminates are needed to enhance the barrier properties of the kraft material. Laminates can improve resistance to moisture, grease, and other potential contaminants.

- Sealing Integrity:

- Ensure that the sealing integrity of the kraft stand-up pouch is robust. Proper sealing prevents moisture ingress, maintains freshness, and prevents the pet food from exposure to external elements. Test the sealing strength to confirm its effectiveness.

- Odor Control:

- Evaluate the potential for odor absorption or transmission between the kraft material and the pet food. Incorporate odor barrier technologies if needed to prevent the transfer of unwanted odors, ensuring that the pet food retains its intended flavor and aroma.

- Compatibility Testing:

- Conduct compatibility testing between the kraft material and the pet food formulation. This may involve assessing the impact of the pet food on the material and vice versa over time. Check for any changes in texture, color, or flavor caused by the interaction between the packaging and the product.

- Regulatory Compliance:

- Ensure that the chosen kraft stand-up pouch materials comply with relevant regulatory standards for food packaging. This includes considerations for food-contact safety, migration limits, and overall compliance with food packaging regulations in the intended market.

- Recyclability and Sustainability:

- Consider the environmental impact of the packaging material. Opt for kraft materials that are recyclable or made from sustainable sources. kraft stand up pouch Communicate the eco-friendly attributes of the packaging to consumers who prioritize sustainability.

- Resealable Features:

- If the pet food requires resealing for freshness, choose kraft stand-up pouches with compatible resealable features. Zippers or other reclosable options should maintain their integrity and functionality throughout the product’s usage.

- Heat Resistance:

- Assess the heat resistance of the kraft material, especially if the pet food requires heat treatment during processing or if the packaging will be exposed to high temperatures during transportation or storage.

- Customization for Pet Food Types:

- Different types of pet food (dry, wet, treats) may have varying requirements. Customize the kraft stand-up pouch specifications based on the specific type of pet food to ensure optimal performance and compatibility.

- Communication with Suppliers:

- Collaborate closely with packaging material suppliers to discuss the specific requirements of the pet food formulation. Suppliers can provide guidance on material selection, testing protocols, and potential enhancements to ensure compatibility.

- Consumer Education:

- Provide clear instructions to consumers regarding the proper handling and storage of pet food in the kraft stand-up pouch. Include information on the packaging about the suitability for specific pet food types and any recommended storage conditions.

By carefully addressing these considerations, manufacturers can ensure that kraft stand-up pouch materials are compatible with various pet food formulations, maintaining product quality and safety throughout the packaging lifecycle. Continuous testing, collaboration with suppliers, and adherence to regulatory standards contribute to the overall success of the packaging solution.

Posted on January 29, 2024

How are environmental sustainability practices integrated into printed stand up pouches production?

The integration of environmental sustainability practices into the production of printed stand-up pouches involves adopting a holistic approach that addresses various aspects of the manufacturing process.

Here are key considerations and practices to achieve environmental sustainability in the production of printed stand-up pouches:

- Material Selection:

- Choose eco-friendly materials, such as recyclable or biodegradable films, for the stand-up pouches. Look for materials that have a lower environmental impact and can be easily recycled or composted.

- Water-Based Inks:

- Use water-based or environmentally friendly inks for printing on the stand-up pouches. Water-based inks typically contain fewer volatile organic compounds (VOCs) compared to solvent-based inks, reducing their environmental impact.

- Printing Technologies:

- Employ eco-friendly printing technologies, such as digital printing or flexographic printing with water-based inks. These technologies often result in less waste, lower energy consumption, and reduced emissions compared to traditional printing methods.

- Energy Efficiency:

- Implement energy-efficient practices in the printing and manufacturing processes. This includes using energy-efficient equipment, optimizing production schedules to reduce downtime, and incorporating energy-saving technologies.

- Waste Reduction:

- Minimize waste by optimizing material usage and adopting practices such as print job consolidation. Consider implementing lean manufacturing principles to reduce excess inventory and waste throughout the production process.

- Recyclability and Compatibility:

- Design stand-up pouches to be easily recyclable. Ensure that the printed materials and any additional components, such as zippers or valves, printed stand up pouches are compatible with existing recycling streams. Clearly communicate recycling instructions to consumers on the packaging.

- Supply Chain Sustainability:

- Collaborate with suppliers who adhere to sustainable practices. This includes sourcing materials from suppliers with responsible environmental policies and considering the overall sustainability of the supply chain.

- Reusable Packaging Options:

- Explore the feasibility of reusable stand-up pouches. Design pouches that can be easily cleaned and reused, reducing the overall demand for single-use packaging.

- Life Cycle Assessments:

- Conduct life cycle assessments to evaluate the environmental impact of the stand-up pouches from raw material extraction to end-of-life. Use this information to identify areas for improvement and make informed decisions on materials and processes.

- Certifications and Standards:

- Seek certifications and adhere to industry standards for environmental sustainability. Certifications such as FSC (Forest Stewardship Council) for responsibly sourced materials or recyclability certifications can enhance the eco-friendly profile of the stand-up pouches.

- Consumer Education:

- Provide clear and accurate information to consumers about the environmental attributes of the stand-up pouches. Educate consumers on proper disposal methods, recycling options, and any special considerations for the packaging.

- Innovative Design for Recycling:

- Design stand-up pouches with recyclability in mind. Considerations such as using mono-material structures or incorporating recyclable materials can facilitate easier recycling and contribute to a circular economy.

- Compostable Options:

- Explore the use of compostable materials for stand-up pouches, especially when suitable for the intended contents. Compostable packaging can contribute to reducing environmental impact when disposed of in industrial composting facilities.

- Continuous Improvement:

- Establish a culture of continuous improvement in environmental sustainability. Regularly review and assess the production processes, materials, and technologies to identify opportunities for further enhancement.

By integrating these practices, manufacturers can produce printed stand-up pouches that align with environmental sustainability goals, reduce environmental impact, and meet the growing demand for eco-friendly packaging solutions. Sustainable packaging practices benefit both the environment and the reputation of businesses that prioritize responsible production.

Posted on January 18, 2024

How do these modules handle mechanical stress and vibration in industrial environments?

Aluminium silicate ceramic fiber modules are designed to withstand mechanical stress and vibration in industrial environments to ensure their structural integrity and long-term performance.

Here are ways in which these modules handle mechanical stress and vibration:

- Flexibility and Resilience:

- Aluminium silicate ceramic fiber modules are known for their flexibility and resilience. This enables them to absorb and withstand moderate mechanical stress without experiencing permanent deformation or damage.

- High-Temperature Stability:

- These modules maintain stability at high temperatures, which is crucial in industrial environments where mechanical stress often accompanies elevated temperatures. The ceramic fibers can maintain their structural integrity even under thermal loads.

- Low Thermal Expansion:

- Aluminium silicate ceramic fibers typically exhibit low thermal expansion characteristics. This property helps the modules maintain their shape and structural integrity when subjected to thermal fluctuations, reducing the risk of mechanical stress.

- Anchoring Systems:

- During installation, aluminium silicate ceramic fiber modules are often secured using anchoring systems. These anchoring systems help distribute mechanical stress evenly and prevent movement or displacement of the modules in response to vibrations or other external forces.

- Reinforced Construction:

- Some aluminium silicate ceramic fiber modules come with reinforced construction, including additional materials or coatings that enhance their mechanical strength.aluminium silicate ceramic fiber modules This reinforcement helps the modules withstand higher levels of mechanical stress.

- Vibration Dampening:

- The inherent properties of ceramic fibers, such as their stiffness and damping capabilities, contribute to the ability of these modules to dampen vibrations. This is particularly important in environments where machinery-induced vibrations are common.

- Customized Designs:

- Aluminium silicate ceramic fiber modules can be customized to specific shapes and sizes. This customization allows for a better fit in industrial settings and helps distribute mechanical stress more effectively.

- Rigorous Testing:

- Manufacturers subject aluminium silicate ceramic fiber modules to rigorous testing, including mechanical stress tests and vibration resistance assessments. This ensures that the modules meet industry standards and can withstand the demands of industrial environments.

- Secure Installation:

- Proper installation techniques, including secure anchoring and fastening, play a crucial role in ensuring that the modules remain in place and effectively handle mechanical stress and vibrations.

- Regular Inspection and Maintenance:

- Regular inspection and maintenance practices are recommended to identify any signs of wear, displacement, or damage. Addressing issues promptly helps maintain the modules’ ability to handle mechanical stress over time.

By combining these design features and installation practices, aluminium silicate ceramic fiber modules can effectively handle mechanical stress and vibrations in industrial environments, contributing to their reliability and longevity in applications such as furnaces, kilns, and other high-temperature processes.