Posted on January 18, 2024

How do Cooler Bag cater to different age groups, such as children, students, or adults?

Cooler bags are versatile accessories that cater to different age groups by offering features and designs tailored to the specific needs and preferences of children, students, and adults.

Here’s how cooler bags can meet the requirements of each age group:

1. Children:

- Fun Designs: Cooler bags for children often feature vibrant colors, playful patterns, and popular cartoon characters to make them visually appealing.

- Lightweight and Portable: Kid-friendly cooler bags are designed to be lightweight and easy for children to carry. They may have smaller sizes suitable for snacks and lunches.

- Durable Materials: Given the likelihood of rough handling, cooler bags for children are often made from durable and easy-to-clean materials.

- Insulation for School Lunches: Cooler bags with effective insulation help keep school lunches fresh and safe for consumption.

2. Students:

- Laptop Compartments: Cooler bags designed for students may include separate compartments for laptops or tablets, providing a convenient all-in-one solution.

- Versatile Styles: Cooler bags come in various styles, from backpacks to messenger bags, catering to the diverse preferences of students.

- Organization Pockets: Students often require organizational features. Cooler bags with multiple pockets help keep items like pens, notebooks, Wholesale Cooler Bag suppliers and snacks well-organized.

- Adjustable Straps: Adjustable and padded shoulder straps enhance comfort during daily commuting to school or college.

3. Adults:

- Sophisticated Designs: Cooler bags for adults often feature sleek and sophisticated designs suitable for workplaces or outdoor gatherings.

- Large Capacities: Cooler bags designed for adults may have larger capacities to accommodate meals for work, picnics, or travel.

- Insulated Compartments: Advanced insulation technology ensures that food and beverages remain at the desired temperature for extended periods.

- Professional Styles: Some cooler bags are designed to resemble professional briefcases or tote bags, allowing adults to carry their meals discreetly.

- Additional Features: Adults may appreciate extra features such as external pockets for utensils, bottle openers, or designated spaces for ice packs.

4. Outdoor Enthusiasts:

- Durable and Weather-Resistant: Cooler bags designed for outdoor activities, like camping or hiking, may be constructed from durable and weather-resistant materials.

- Attachment Points: Outdoor cooler bags may have attachment points for additional gear, making them suitable for various adventures.

- MOLLE Straps: Some outdoor cooler bags feature MOLLE (Modular Lightweight Load-carrying Equipment) straps, allowing users to customize and attach accessories.

5. Elderly Individuals:

- Easy Accessibility: Cooler bags for elderly individuals may prioritize easy accessibility, with wide openings and simple closure mechanisms.

- Lightweight Construction: Considering potential mobility challenges, cooler bags for the elderly are often designed to be lightweight.

- Adjustable Straps: Adjustable and padded straps provide comfortable carrying options.

By addressing the specific needs and preferences of different age groups, cooler bags become versatile accessories suitable for a wide range of users and occasions. Whether it’s for school, work, outdoor adventures, or daily activities, cooler bags can be adapted to meet diverse requirements.

Posted on January 6, 2024

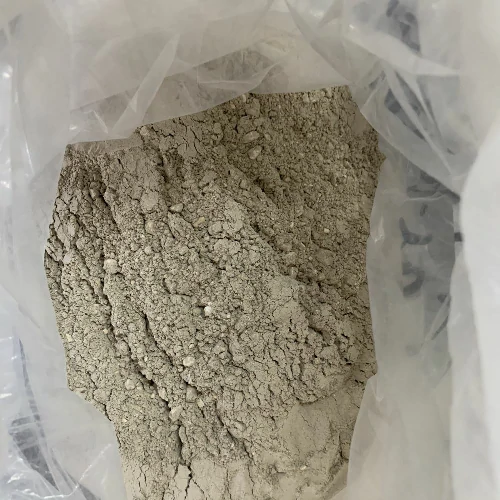

Low Cement Castable: The Next Evolution in High-Performance Refractories

Low cement castable refractories represent a significant innovation in the realm of refractory materials, offering exceptional strength, thermal shock resistance, and superior performance in high-temperature environments. Engineered with reduced cement content, these castables provide remarkable durability and stability in diverse industrial applications where extreme heat and harsh conditions prevail.

Understanding Low Cement Castable Refractories

- Composition: Low cement castables feature a reduced proportion of cement compared to conventional castables. They primarily consist of high-quality refractory aggregates, fine powders, and carefully selected bonding agents.

- Advanced Binders: Sophisticated binders, such as ultrafine particles and reactive alumina additives, enhance particle packing and reduce porosity, contributing to improved mechanical properties.

Key Features and Benefits

- Enhanced Strength: Reduced cement content results in higher strength and density, offering superior mechanical properties, abrasion resistance, and structural integrity in high-temperature environments.

- Thermal Shock Resistance: These castables exhibit excellent resistance to thermal shock, maintaining stability and performance even in rapid temperature variations or severe thermal cycling.

- Lower Porosity: The decreased cement content leads to reduced porosity, minimizing gas permeability and enhancing resistance to slag penetration and chemical attack.

Applications in Various Industries

- Steel and Metal Industries: Low cement castables find use in steelmaking, ladles, tundishes, and other high-temperature vessels, providing superior lining solutions for improved performance and durability.

- Incinerators and Petrochemical Plants: They serve as linings in rotary kilns, boilers, and reactors, offering exceptional thermal insulation and chemical resistance in harsh environments.

- Cement and Ceramics Manufacturing: These castables are utilized in cement kilns, preheaters, and ceramic kilns, ensuring reliability and longevity in high-temperature production processes.

Benefits for Industrial Applications

- Optimized Performance: The advanced formulation of low cement castables enhances refractory performance, reducing downtime and maintenance costs in industrial operations.

- Energy Efficiency: Their superior thermal conductivity and insulation properties contribute to energy savings by reducing heat loss and improving furnace efficiency.

Considerations and Installation

- Material Selection: Tailoring the composition of low cement castables to suit specific temperature ranges and environmental conditions is crucial for optimal performance in different industrial settings.

- Installation Techniques: These castables are installed by casting, gunning, or shotcreting methods, ensuring proper placement, consolidation, and curing to achieve desired thermal efficiency and stability.

Low cement castable refractories represent a significant advancement in high-performance refractory materials, offering exceptional strength, thermal shock resistance, and durability in extreme heat applications. Their ability to withstand severe conditions, coupled with improved mechanical properties and reduced porosity, makes them indispensable in steel, petrochemical, cement, and ceramics industries. Understanding their composition and application benefits empowers industries to leverage these advanced castables effectively, ensuring enhanced performance, extended service life, and reliability in high-temperature environments.

Posted on January 4, 2024

What are the characteristics of the midsole cushioning technology used in SACAI, and how to improve comfort?

SACAI, known for its collaborations with Nike, often incorporates various midsole cushioning technologies. While the specifics may vary based on the specific collaboration or model, a few characteristics and approaches to improve comfort might include:

- Combination of Technologies: SACAI often merges multiple cushioning technologies. For instance, they might combine Nike’s React foam with traditional Nike Air cushioning or other proprietary technologies to achieve a balance of responsiveness, cushioning, and impact absorption.

- Enhanced Responsiveness: SACAI’s designs may aim to enhance responsiveness by utilizing advanced foam compounds or incorporating innovative cushioning systems. This helps provide a more energetic and comfortable feel during movement.

- Layered Approach: Some SACAI designs feature layered midsoles, combining different foam densities or materials. This stratification is intended to optimize cushioning, stability, and energy return, leading to enhanced comfort.

- Customized Fit: SACAI might employ design elements like exaggerated midsoles or extended cushioning units, China SACAI suppliers offering a unique visual aesthetic while potentially providing additional comfort by altering the foot strike or weight distribution.

- Impact Absorption: The cushioning technology likely focuses on superior impact absorption to reduce strain on the feet and joints, enhancing overall comfort, especially during high-impact activities.

- Adaptive and Supportive: SACAI’s approach might involve cushioning that adapts to the foot’s movement while providing essential support, contributing to a comfortable and stable wearing experience.

The specific characteristics of SACAI’s midsole cushioning can vary depending on the collaboration and the specific technologies employed in each shoe model. However, these general traits often underlie their designs, aiming to optimize comfort, responsiveness, and support for wearers.

Posted on December 26, 2023

Learn all about grooved mechanical tee: Functions, Uses, and Benefits

The grooved mechanical tee is a specialized fitting used in piping systems to create branch connections. It offers several functions, uses, and benefits that make it popular in various industries. In this explanation, we’ll explore the key aspects of grooved mechanical tees.

What is a Grooved Mechanical Tee?

A grooved mechanical tee is a pipe fitting designed with grooved ends that allow for quick and efficient installation. It consists of three connection points: a mainline end, an outlet end, and a branch end. The mainline end connects to the primary pipe, while the outlet end provides a connection for a secondary pipe. The branch end allows for the attachment of a third pipe, creating a branch connection.

Functions of Grooved Mechanical Tees:

Branch Connections: The primary function of a grooved mechanical tee is to create branch connections in a piping system. It enables the addition of new pipelines without the need for complex cutting, welding, or threading processes. This makes it ideal for applications where branch connections need to be made quickly and easily.

Uses of Grooved Mechanical Tees:

Grooved mechanical tees find applications in various industries and systems, including:

Fire Protection Systems: Grooved mechanical tees are commonly used in fire protection systems to create branch connections for sprinkler systems, standpipes, and other fire suppression equipment. They allow for the rapid installation and expansion of the fire protection network.

HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, grooved mechanical tees are employed to create branch connections for chilled water, hot water, and other fluid distribution lines. They simplify the installation and maintenance of HVAC piping systems.

Process Piping: Grooved mechanical tees are used in process piping applications, such as in industrial plants, refineries, and manufacturing facilities. They enable the creation of branch connections for the transport of various liquids, gases, and chemicals.

Water and Wastewater Systems: These tees are utilized in water supply and wastewater systems to create branch connections for distribution and collection pipelines. They facilitate the efficient installation and expansion of municipal, commercial, and residential water networks.

Mining and Oil & Gas Industries: Grooved mechanical tees are employed in mining and oil & gas industries for branch connections in pipelines used for transporting fluids, such as water, oil, and gas.

Benefits of Grooved Mechanical Tees:

Ease of Installation: Grooved mechanical tees allow for quick and straightforward installation. The grooved ends eliminate the need for welding, threading, or flanging, reducing labor time and costs.

Modularity and Flexibility: These tees offer flexibility in system design and modifications. They can be easily disassembled and reassembled, allowing for system expansion, reconfiguration, or relocation.

Reliability and Leak Resistance: The grooved coupling system provides a secure and leak-resistant joint. When properly installed, it offers excellent resistance to internal and external pressures, ensuring system integrity.

Vibration and Noise Reduction: Grooved mechanical tees absorb and dampen vibrations and noise generated by fluid flow, resulting in quieter and more stable operation of the piping system.

Maintenance and Repairs: The modular design of grooved mechanical tees simplifies maintenance and repairs. If necessary, the tee can be easily replaced or removed for inspection or maintenance purposes without disrupting the entire system.

It’s important to note that the specific design, size, and materials of grooved mechanical tees may vary depending on the manufacturer and application requirements. Always refer to the manufacturer’s guidelines and industry standards when selecting and installing grooved mechanical tees in a piping system.

By understanding the functions, uses, and benefits of grooved mechanical tees, you can make informed decisions when incorporating them into your piping systems.

Posted on December 16, 2023

What is the quality of white winter bedding?

The quality of white winter bedding, like any other bedding, can vary based on several factors, including materials, thread count, construction, and personal preferences. However, when it comes to winter bedding specifically, certain qualities are typically sought after to ensure warmth, comfort, and durability during colder months.

Materials:

- Natural Fibers: High-quality winter bedding often uses natural fibers such as cotton, linen, or wool. Cotton flannel and brushed cotton are popular choices for winter due to their softness, breathability, and ability to retain warmth.

- Warmth-Retaining Fabrics: Bedding made from materials like flannel, fleece, or heavier-weight cotton can provide better insulation and warmth during colder temperatures.

Thread Count:

- Moderate to High Thread Count: A moderate to high thread count in cotton bedding generally indicates a smoother, softer fabric. However, for winter bedding, a slightly lower thread count (around 200-400) can be preferable as it allows for better breathability while retaining warmth.

Construction:

- Quality Stitching: Strong and durable stitching ensures the bedding withstands regular use and washing without fraying or coming apart.

Insulation and Comfort:

- Thermal Insulation: Winter bedding should provide adequate insulation to keep the body warm without causing overheating. Fabrics that trap body heat without feeling overly heavy or suffocating are desirable.

- Softness and Comfort: Bedding should feel soft and comfortable against the skin to ensure a good night’s sleep.

Maintenance:

- Ease of Care: High-quality winter bedding should be easy to maintain and clean. It’s advisable to check the care instructions to ensure proper washing and maintenance procedures.

Appearance and Design:

- Color Retention: For white winter bedding, quality includes maintaining its crisp white color after multiple washes.

- Aesthetic Appeal: Aesthetic features like a smooth finish, neat edges, and an overall appealing appearance contribute to the perceived quality of the bedding.

Brand Reputation and Reviews:

- Reputable Brands: Bedding from reputable brands often maintains higher quality standards in terms of materials, construction, and customer satisfaction.

When choosing white winter bedding, it’s essential to consider personal preferences for warmth, comfort, and material preferences. Reading product descriptions, checking reviews from other buyers, and understanding the specific materials used in the bedding can help in assessing its overall quality. Ultimately, the right winter bedding is one that provides the desired level of warmth, comfort, durability, and aesthetic appeal to suit individual needs during the colder months.

What is there for white winter bedding?

White winter bedding encompasses a range of bedding essentials specifically designed to provide warmth, comfort, and a cozy atmosphere during the colder winter months.

Here are some common items and considerations when it comes to white winter bedding:

Sheets and Pillowcases:

- Flannel Sheets: Flannel sheets are soft and cozy, often made from cotton or a cotton-blend fabric. They offer warmth and comfort, ideal for chilly nights.

- Brushed Cotton Sheets: Similar to flannel, brushed cotton sheets have a soft, fuzzy texture that adds warmth and comfort during winter.

- Egyptian Cotton Sheets: High-quality Egyptian cotton sheets in white can provide a luxurious feel while offering warmth and breathability.

Duvet Covers and Comforters:

- White Duvet Covers: White duvet covers made from materials like cotton, linen, or microfiber can be used to cover comforters or duvets, adding an elegant and clean look to the bedding ensemble.

- Down Comforters: White down comforters are popular for their insulation properties, providing warmth without excessive weight.

Blankets and Throws:

- Fleece Blankets: Soft and plush fleece blankets in white offer additional warmth when layered on the bed.

- Knit Throws: Knit throws or blankets in white can add texture and warmth to the bedding while enhancing the visual appeal.

Pillow Shams and Decorative Pillows:

- White Pillow Shams: Pillow shams in white complement the bedding set and can be used as decorative covers for pillows.

- Accent Pillows: Adding decorative accent pillows in various textures or patterns can enhance the overall aesthetic of the bed while adding warmth and comfort.

Mattress Toppers and Protectors:

- Memory Foam or Down Mattress Toppers: These can add an extra layer of comfort and warmth to the bed while providing additional support.

- Mattress Protectors: Waterproof or quilted mattress protectors in white can safeguard the mattress while adding a layer of warmth.

Considerations:

- Material and Warmth: Opt for bedding materials known for their warmth, such as flannel, fleece, brushed cotton, or down-filled items.

- Layering: Layering bedding items can help adjust warmth levels based on personal preference and the fluctuating temperature throughout the night.

- Quality and Maintenance: Look for high-quality materials and construction that are easy to care for and maintain, ensuring longevity.

- Personal Style: While white bedding offers a clean and classic look, consider adding texture, patterns, or accents to match personal style preferences.

White winter bedding provides a versatile canvas for creating a cozy and inviting sleep environment during colder seasons. By selecting quality materials and layering bedding essentials, you can achieve both warmth and an aesthetically pleasing bedroom decor.

Posted on December 8, 2023

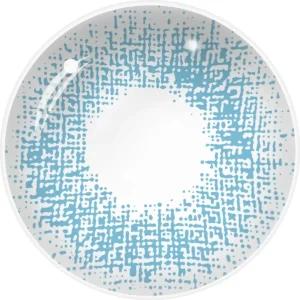

What effect will blue contact lenses have to wear ?

Wearing blue contact lenses can have several effects on your appearance and can be used for various purposes.

Here are some potential effects of wearing blue contact lenses:

- Eye Color Enhancement: Blue contact lenses can enhance or change the natural color of your eyes. They can make your eye color appear brighter, more vibrant, and more intense. If you have light-colored eyes, blue lenses can enhance the blue tones, while for dark-colored eyes, they can provide a noticeable change in eye color.

- Aesthetic Variety: Blue contact lenses offer a wide range of aesthetic options. They come in different shades and patterns of blue, allowing you to choose the specific look you desire. Whether you prefer a subtle, natural blue or a bold, vivid blue, there are various options available to suit your preferences.

- Transformation and Cosplay: Blue contact lenses are commonly used in cosplay (costume play) and for costume parties. They can help you accurately portray characters with blue eyes, such as anime characters or certain fictional characters. Blue lenses can add authenticity to your costume and enhance your overall transformation.

- Fashion and Style: Wearing blue contact lenses can be a fashion statement, allowing you to express your personal style and individuality. Blue eyes are often associated with beauty and are considered appealing by many. Blue lenses can help you achieve a desired aesthetic or create a specific look that aligns with your fashion preferences.

- Subtle Change or Bold Transformation: Depending on the shade and intensity of the blue lenses, the effect can range from a subtle enhancement of your natural eye color to a complete transformation. Lighter shades of blue may provide a more subtle change, while darker or more vibrant blue lenses can create a bolder and more noticeable transformation.

It’s important to note that while blue contact lenses can offer aesthetic benefits, they should be used responsibly blue colored contact lenses 10 lenses and with proper care. It is essential to consult with an eye care professional and obtain a prescription for contact lenses to ensure a proper fit and to maintain eye health and safety. Improper use or sharing of contact lenses can lead to eye irritation, discomfort, and potentially more severe eye problems.

When wearing blue contact lenses, in addition to the effects mentioned above, there are some other aspects to understand:

- Natural and realistic: High quality blue contact lenses are designed to be very realistic, making the eyes look more natural. They are often dyed with special techniques to mimic real eye color and texture, making it difficult for people to detect that you are wearing contact lenses.

- Personality and self-expression: Blue contact lenses can help you show personality and self-expression. Whether you choose a bright, vivid blue or a soft, deep blue, it will highlight your unique style and personality. They attract others’ attention and make you stand out from the crowd.

- Acting and photography: Blue contact lenses are often used in acting and photography. They can add drama to a character and create special visual effects. In movies, TV shows or commercials, blue contact lenses can be used to depict supernatural characters, science fiction or fantasy characters, or to add an artistic touch to photography.

- Fashion and trends: Blue contact lenses can follow fashion trends and help you show a distinctive fashion style. Blue eyes are often considered an attractive and attractive feature, and wearing blue contact lenses can help you achieve this stylish effect.

- Confidence and changing your appearance: By changing your eye color, wearing blue contact lenses can boost your confidence. They can give you a whole new look and make you feel different. This change may boost your self-esteem and make you feel more confident in different social situations.

Overall, blue contact lenses can add some unique features to your appearance, helping you achieve a personalized style and image. However, in order to protect the health and safety of your eyes, it is important to follow professional advice and guidelines for the use of contact lenses. Before choosing and using blue contact lenses, it is recommended to consult an ophthalmologist or professional to ensure the right way to wear and maintain them, as well as the health and safety of your eyes.

Updated on December 1, 2023

How is the pump flow rate calculation and

The pump flow rate calculation depends on the type of pump and the available information.

Here are a few common methods used to calculate pump flow rate:

- Positive Displacement Pump: For positive displacement pumps, such as reciprocating pumps or rotary pumps, the flow rate can be calculated by measuring the displacement per stroke or the volume per revolution. The pump’s specifications or design parameters provide this information. The flow rate (Q) can be calculated using the formula: Q = Displacement per stroke (or volume per revolution) × Pump speed (strokes per minute or revolutions per minute).

- Centrifugal Pump: For centrifugal pumps, the flow rate is typically determined by the pump’s performance characteristics, such as the pump curve. The pump curve provides the relationship between the flow rate and the head (pressure) generated by the pump. By knowing the head and selecting a point on the pump curve, the corresponding flow rate can be obtained.

- Flow Meter: Another common method to calculate pump flow rate is by using a flow meter installed in the pump’s discharge line. Flow meters, such as electromagnetic, ultrasonic, or turbine flow meters, directly measure the flow rate of the fluid passing through them. These flow meters provide real-time flow rate readings.

- Pump Efficiency: In some cases, the pump flow rate may be calculated indirectly by measuring the power input to the pump and the pump efficiency. The flow rate (Q) can be determined using the formula: Q = Power input / (Fluid density × Gravity × Pump efficiency), where the power input is measured in watts, fluid density is measured in kilograms per cubic meter, and gravity is approximately 9.81 m/s².

It’s important to note that pump flow rate calculations may involve additional factors, such as fluid viscosity, temperature, and system pressure, depending on the specific application. Additionally, different pump types and designs may require specific equations or considerations for accurate flow rate calculations. Consulting the pump manufacturer’s documentation or seeking professional engineering assistance is recommended for precise flow rate calculations.

Where is pump flow rate calculation generally applied ?

Pump flow rate calculations are applied in various industries and applications where the accurate measurement and control of fluid flow is important. Some common areas where pump flow calculations are utilized include:

- Water and Wastewater Treatment: Pump flow calculations are crucial in water treatment plants, wastewater treatment facilities, and water distribution systems. The flow rate of water or wastewater needs to be accurately measured and controlled to ensure efficient treatment processes, maintain desired water quality, and optimize system performance.

- Industrial Processes: Pump flow rate calculations are essential in industrial processes that involve the transportation of fluids, such as chemical manufacturing, oil and gas production, pharmaceutical production, food and beverage processing, and pulp and paper industry. Accurate flow rate measurements and control are necessary for process optimization, product quality assurance, and regulatory compliance.

- HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, pump flow calculations are used to determine the flow rate of chilled water, hot water, or other fluids for space heating, cooling, and distribution. Proper flow rate control ensures optimal system performance, energy efficiency, and thermal comfort.

- Oil and Gas Industry: Pump flow calculations play a vital role in the oil and gas industry for processes such as crude oil pumping, pipeline transportation, refinery operations, and well stimulation. Accurate flow rate measurements are crucial for production optimization, pipeline integrity, and overall operational efficiency.

- Power Generation: Pump flow rate calculations are employed in power generation facilities, including thermal power plants, nuclear power plants, and renewable energy systems. Determining the flow rate of cooling water, fuel, or other fluids is essential for efficient heat transfer, equipment cooling, and power generation.

- Laboratory Research: In scientific laboratories, pump flow rate calculations are used in various research applications, such as chromatography, liquid handling systems, and sample analysis. Precise flow rate control ensures accurate and repeatable experiments and measurements.

- Medical and Healthcare: Pump flow calculations are utilized in medical and healthcare settings for applications like drug delivery, intravenous therapy, dialysis, and circulation support devices. Accurate flow rate control is critical for patient safety, medication dosage accuracy, and therapeutic effectiveness.

These are just a few examples of the broad range of areas where pump flow rate calculations are applied. In general, any industry or application that involves the movement, control, or measurement of fluids relies on accurate flow rate calculations to ensure optimal performance, efficiency, and safety.

Posted on November 24, 2023

Agricultural Tomato Greenhouses: Cultivating Quality, Sustainability, and Year-Round Harvests

Agricultural tomato greenhouses have revolutionized the way tomatoes are grown and supplied to markets worldwide. These controlled environments offer numerous advantages, enabling growers to optimize growing conditions, enhance crop quality, and extend the harvest season. In this article, we delve into the world of agricultural tomato greenhouses, exploring their benefits, technologies, and contributions to sustainable agriculture.

Here are some descriptions of agricultural tomato greenhouses:

Extended Growing Season

One of the primary advantages of agricultural tomato greenhouses is the ability to extend the growing season. By providing a controlled environment, growers can protect tomato plants from adverse weather conditions, including frost, excessive heat, and heavy rains. This means that tomatoes can be cultivated year-round, ensuring a consistent supply of fresh, ripe tomatoes regardless of the external climate.

Enhanced Crop Quality:

Tomatoes grown in agricultural greenhouses often exhibit superior quality compared to field-grown counterparts. The controlled environment allows growers to regulate temperature, humidity, and light levels, creating optimal conditions for tomato growth. With precise control over factors such as irrigation, nutrient delivery, and pest management, greenhouse tomatoes can have enhanced flavor, vibrant color, and uniform size and shape.

Disease and Pest Control:

Greenhouse cultivation provides a physical barrier between tomato plants and external pathogens, minimizing the risk of diseases and pests. By excluding common tomato threats such as soil-borne diseases, insects, and weeds, greenhouse growers can reduce or eliminate the need for chemical treatments. This not only enhances plant health but also contributes to environmentally friendly and sustainable agricultural practices.

Water and Resource Efficiency:

Agricultural tomato greenhouses are designed to maximize resource efficiency. Advanced irrigation systems, such as drip irrigation or hydroponics, enable precise water delivery, minimizing water waste. Additionally, water and nutrient recycling systems allow for efficient reuse, reducing the overall water and fertilizer consumption. This resource-conscious approach helps conserve water, reduce environmental impact, and optimize production efficiency.

Climate Control and Adaptability:

Greenhouse technology allows growers to exert precise control over environmental factors such as temperature, humidity, and light. By utilizing heating, cooling, and ventilation systems, growers can create an optimal climate for tomato cultivation, regardless of the external conditions. This adaptability is particularly beneficial in regions with extreme climates or areas where tomatoes are not traditionally grown.

Increased Yields and Productivity:

Agricultural tomato greenhouses are associated with higher yields and increased productivity compared to field cultivation. The controlled environment and optimized growing conditions promote healthy plant growth, efficient nutrient uptake, and increased photosynthesis, leading to more abundant harvests. This improved productivity not only benefits farmers but also ensures a stable supply of tomatoes for consumers.

Sustainable and Controlled Environment:

Greenhouse tomato production is inherently more sustainable than traditional field cultivation. The controlled environment reduces the need for synthetic pesticides and fertilizers, minimizing the environmental impact. Moreover, the efficient use of resources, water conservation practices, and reduced carbon emissions contribute to sustainable agricultural practices. Greenhouse cultivation also allows for the implementation of integrated pest management strategies, promoting biodiversity and ecosystem health.

Agricultural tomato greenhouses have revolutionized the tomato industry, providing growers with a controlled environment to optimize growing conditions, enhance crop quality, and extend the harvest season. The benefits of greenhouse tomato cultivation include extended growing seasons, superior crop quality, disease and pest control, resource efficiency, climate adaptability, increased yields, and sustainable practices. As the demand for high-quality tomatoes grows year-round, agricultural tomato greenhouses have emerged as a key solution, ensuring a steady supply of fresh, flavorful tomatoes while contributing to sustainable and environmentally conscious agriculture.

Here are some additional details about agricultural tomato greenhouses:

- Greenhouse Types:

Agricultural tomato greenhouses come in various designs, including glass or plastic structures. Glass greenhouses offer excellent light transmission and durability, while plastic greenhouses are more cost-effective and provide good insulation. Greenhouse structures can be tailored to the specific needs of tomato cultivation, incorporating features such as automated ventilation, shading systems, and climate control technologies. - Tomato Varieties:

Greenhouse tomato cultivation allows for the production of a wide range of tomato varieties, including cherry tomatoes, beefsteak tomatoes, heirloom tomatoes, and specialty varieties. The controlled environment of the greenhouse enables growers to create optimal conditions for each variety, ensuring consistent quality, flavor, and appearance. - Pollination:

In greenhouse tomato cultivation, proper pollination is crucial for fruit set and yield. Since natural pollinators may not have access to the enclosed environment, growers often employ alternative pollination methods. This can involve manual pollination using vibrating tools, introducing bumblebees or other pollinators into the greenhouse, or utilizing mechanical pollination techniques. - Trellising and Training Systems:

To maximize space utilization and support the vigorous growth of tomato plants, trellising and training systems are commonly used in greenhouse cultivation. These systems involve training the tomato plants to grow vertically along strings or trellises, allowing for better air circulation, easier access for maintenance and harvesting, and minimizing the risk of disease transmission. - Greenhouse Technology:

Greenhouse technology continues to advance, offering growers innovative tools to optimize tomato production. This includes automated climate control systems that regulate temperature, humidity, and ventilation, as well as computerized irrigation systems that deliver precise amounts of water and nutrients. Additionally, sensor technologies can monitor environmental conditions and provide real-time data for growers to make informed decisions about crop management. - Integrated Pest Management (IPM):

Agricultural tomato greenhouses often employ integrated pest management strategies to control pests and diseases. IPM combines various methods, including biological controls (such as introducing beneficial insects), cultural practices (such as proper sanitation and crop rotation), and judicious use of pesticides as a last resort. This approach minimizes the reliance on synthetic chemicals and promotes a balanced ecosystem within the greenhouse. - Market Demand and Consumer Preferences:

The demand for greenhouse-grown tomatoes continues to rise due to consumer preferences for high-quality, locally sourced produce year-round. Greenhouse cultivation allows for consistent supply, reliable quality, and reduced transportation distances, meeting the demands of consumers who seek fresh, flavorful tomatoes regardless of the season. - Research and Innovation:

Ongoing research and innovation in greenhouse tomato cultivation are driving advancements in plant breeding, crop management techniques, and sustainable practices. Scientists and growers collaborate to develop new tomato varieties with improved traits, optimize resource use efficiency, and implement environmentally friendly production methods. This dedication to innovation ensures continuous improvement and sustainability in greenhouse tomato cultivation.

Agricultural tomato greenhouses provide a controlled environment that enables growers to produce high-quality tomatoes year-round. With advancements in greenhouse technology, innovative cultivation techniques, and sustainable practices, greenhouse tomato production continues to evolve, meeting the demands of consumers for fresh, flavorful, and sustainably grown tomatoes. As the industry progresses, the future of agricultural tomato greenhouses looks promising, offering increased efficiency, improved crop quality, and a more sustainable approach to tomato cultivation.

Posted on November 24, 2023

Growing Possibilities: Plants Thriving in a Blackout Greenhouse

Blackout greenhouses, also known as light deprivation or light-blocking greenhouses, have gained popularity in recent years for their ability to provide precise control over light exposure. These specialized structures allow growers to manipulate the photoperiod and create optimal growing conditions for various plants.

Here is the diverse range of plants that can flourish in a blackout greenhouse, unlocking new possibilities for year-round cultivation and increased crop productivity.

Cannabis:

Blackout greenhouses have become particularly renowned in the cultivation of cannabis. These structures enable growers to manipulate the light cycle, mimicking the natural daylight patterns and controlling the flowering phase of the plants. By carefully managing the photoperiod, growers can induce flowering at desired times, leading to increased control over yield, potency, and harvest schedules.

Leafy Greens:

Leafy greens such as lettuce, spinach, kale, and arugula can thrive in blackout greenhouses. By controlling the light exposure, growers can stimulate rapid growth and achieve consistent leaf production throughout the year. The ability to regulate the photoperiod also allows for precise timing in crop scheduling, ensuring a constant supply of fresh, high-quality greens.

Herbs:

A blackout greenhouse provides an excellent environment for growing a variety of herbs, including basil, parsley, cilantro, and mint. These plants often benefit from extended periods of darkness during their growth cycle, which can enhance flavor and aroma. With the ability to precisely manipulate the light, growers can optimize herb production and meet the demands of the culinary market.

Flowers:

Blackout greenhouses offer immense possibilities for cultivating flowers with specific flowering requirements. Plants such as chrysanthemums, poinsettias, and certain orchid varieties can benefit from controlled light exposure to induce and synchronize blooming. By carefully managing the photoperiod, growers can extend the flowering season, enhance flower quality, and ensure a consistent supply throughout the year.

Fruiting Vegetables:

Certain fruiting vegetables, including tomatoes, cucumbers, and peppers, can be successfully grown in blackout greenhouses. By manipulating the light cycle to mimic seasonal changes, growers can stimulate flower production and ensure optimal fruit set. This controlled environment allows for extended growing seasons, increased yields, and the production of high-quality fruits.

Microgreens:

Microgreens are young, tender greens that are harvested at an early stage of growth. They are packed with nutrients and have gained popularity in the culinary world. Blackout greenhouses provide an ideal environment for cultivating microgreens due to their ability to control light exposure, resulting in uniform growth and vibrant colors. Growers can efficiently produce a wide variety of microgreens year-round.

Medicinal Plants and Specialty Crops:

Blackout greenhouses offer opportunities for the cultivation of various medicinal plants and specialty crops. Plants such as ginseng, lavender, echinacea, and saffron can benefit from the precise light control provided by a blackout greenhouse. This enables growers to optimize the growth conditions, enhance active compound production, and meet the specific requirements of these valuable crops.

The versatility of blackout greenhouses opens up a world of possibilities for growers seeking precise control over light exposure. From cannabis and leafy greens to herbs, flowers, fruiting vegetables, microgreens, and specialty crops, wholesale blackout greenhouse provides the opportunity to cultivate a diverse range of plants throughout the year. With the ability to manipulate the photoperiod, growers can optimize growth cycles, increase crop productivity, and meet the demands of a variety of markets. Embracing the blackout greenhouse technology empowers growers to explore new horizons in year-round cultivation and sustainable agriculture.

Here are some additional details about growing plants in a blackout greenhouse:

- Berries:

Many berry varieties, including strawberries, raspberries, and blackberries, can be successfully grown in a blackout greenhouse. By manipulating the light exposure, growers can extend the growing season, enhance fruit production, and improve the quality of berries. Blackout greenhouses protect the plants from adverse weather conditions and pests, resulting in healthier plants and higher yields. - Root Vegetables:

Certain root vegetables, such as carrots, beets, and radishes, can be cultivated in a blackout greenhouse. While these crops do not rely heavily on light exposure for growth, blackout greenhouses provide a controlled environment that protects the plants from temperature fluctuations and pests. This controlled environment can lead to more consistent growth and higher-quality root vegetables. - Specialty Greens:

In addition to leafy greens, blackout greenhouses are ideal for growing specialty greens like Swiss chard, mustard greens, and baby bok choy. These greens often have specific temperature and light requirements, which can be easily controlled in a blackout greenhouse. Growers can manipulate the light exposure to optimize growth, color, and flavor, ensuring a desirable product for the market. - Culinary and Medicinal Herbs:

Beyond the commonly grown herbs, blackout greenhouses offer an excellent environment for cultivating a wide range of culinary and medicinal herbs. Plants like rosemary, thyme, oregano, and lavender can benefit from the controlled light exposure provided by a blackout greenhouse. This controlled environment promotes vigorous growth, enhances essential oil production, and ensures consistent quality. - Exotic and Tropical Plants:

Blackout greenhouses enable the successful cultivation of exotic and tropical plants that require specific light conditions. Plants such as orchids, bromeliads, and tropical ferns can thrive in a blackout greenhouse where growers can precisely control the light cycle to mimic their native environments. This allows for year-round cultivation of these unique and sought-after plants. - Mushrooms:

Mushrooms, such as oyster mushrooms and shiitake mushrooms, can be grown in a blackout greenhouse. These fungi have specific light and humidity requirements, which can be carefully managed in a blackout greenhouse environment. By controlling the light exposure and providing the necessary humidity levels, growers can create optimal conditions for mushroom cultivation throughout the year. - Aquaponics and Hydroponics:

Blackout greenhouses are also well-suited for aquaponic and hydroponic systems. These innovative growing methods allow plants to be cultivated without soil, using nutrient-rich water solutions. The controlled environment of a blackout greenhouse provides the ideal conditions for these systems, allowing for efficient water and nutrient management, high crop yields, and reduced water usage.

The possibilities for growing plants in a blackout greenhouse are vast and diverse. From berries and root vegetables to specialty greens, herbs, exotic plants, mushrooms, and innovative growing systems, blackout greenhouses offer a controlled environment to meet the specific needs of various plants. By manipulating the light exposure and creating optimal growing conditions, growers can maximize crop productivity, extend growing seasons, and produce high-quality, market-ready plants throughout the year. The versatility and adaptability of blackout greenhouse technology continue to unlock new opportunities in sustainable agriculture and diversified crop production

Posted on November 10, 2023

A Comprehensive Guide to Selecting a High-Quality High-Strength Aluminum Silicate Plate Manufacturer

Choosing a reliable and high-quality high-strength aluminum silicate plate manufacturer is crucial to ensure the performance, durability, and safety of your applications. With numerous manufacturers available, it is essential to consider key factors that determine their expertise, quality standards, and overall reputation. In this article, we will provide a comprehensive guide to help you choose a good quality high-strength aluminum silicate plate manufacturer.

Reputation and Industry Experience

Look for manufacturers with a solid reputation and extensive experience in producing high-strength aluminum silicate plates. Research their background, customer feedback, and industry standing to assess their reliability and expertise. A manufacturer with a positive reputation is more likely to provide high-quality products and services.

Quality Control and Certifications

Ensure that the manufacturer has robust quality control processes in place to maintain consistent product quality. Look for certifications such as ISO 9001, which demonstrates adherence to international quality standards. Inquire about their quality control measures, including material sourcing, production processes, and final inspection.

- Research and Development (R&D) Capabilities:

Evaluate the manufacturer’s R&D capabilities and technical expertise. A manufacturer that invests in research and development demonstrates a commitment to innovation and continuous improvement. Their ability to develop advanced products and customize solutions to meet specific requirements is advantageous. - Manufacturing Facilities and Equipment:

Inquire about the manufacturer’s manufacturing facilities and equipment. State-of-the-art facilities and modern equipment contribute to efficient production processes and ensure consistent quality. Adequate production capacity is also important to meet your demand in a timely manner. - Material Selection and Testing:

Assess the manufacturer’s approach to material selection and testing. They should use high-quality raw materials and have a comprehensive understanding of their properties. Inquire about their testing procedures to ensure product quality and performance, including mechanical strength, thermal insulation properties, and durability. - Certifications and Compliance:

Verify if the manufacturer complies with relevant industry standards and regulations. Certifications such as RoHS compliance ensure that the products are free from hazardous substances. Compliance with environmental and safety regulations is essential for sustainable and reliable manufacturing practices. - Customer Support and After-Sales Service:

Evaluate the manufacturer’s customer support and after-sales service. A reputable manufacturer should provide responsive and reliable customer support, addressing any queries or concerns promptly. Inquire about their warranty policies and willingness to assist with any product-related issues that may arise. - Cost and Value:

Consider the manufacturer’s pricing in relation to the quality of their products and services. While cost is a factor, prioritize value for money rather than solely focusing on the lowest price. Assess the overall quality, performance, and long-term benefits offered by the manufacturer’s high-strength aluminum silicate plates. - Industry References and Partnerships:

Research the manufacturer’sexisting partnerships and collaborations within the industry. Strong relationships with reputable organizations and industry players can indicate the manufacturer’s credibility and competence. Look for references and testimonials from customers in similar industries to gauge their satisfaction and success with the manufacturer’s products. - Supply Chain and Timely Delivery:

Evaluate the manufacturer’s supply chain management system and ability to meet your supply requirements. Ensure that they have a reliable network of suppliers and can guarantee timely delivery of products. A manufacturer with a streamlined supply chain reduces the risk of delays or disruptions in your operations.

Choosing a good quality high-strength aluminum silicate plate manufacturer requires careful consideration of various factors. Assessing their reputation, industry experience, quality control processes, certifications, technical expertise, customer support, high strength aluminium silicate board manufacturer and value for money will help you make an informed decision. By selecting a reliable manufacturer, you can ensure the consistent quality, performance, and durability of high-strength aluminum silicate plates for your applications.