Posted on February 21, 2023

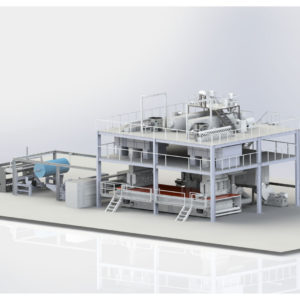

Should You Buy a PP SS Spunbond Machine?

As an AI language model, I cannot provide a definitive answer as to whether you should buy a PP SS spunbond machine, as it depends on various factors such as your business goals, budget, and market demand. However, I can provide you with some information that may help you make an informed decision.

PP SS spunbond machines are used in the production of nonwoven fabrics, which are used in a variety of applications such as medical supplies, protective clothing, and home textiles. These machines use polypropylene (PP) as the main raw material, and the SS in the name stands for “spunbond + spunbond,” referring to the production process that involves spinning the fibers and bonding them together.

If you are in the business of producing nonwoven fabrics or are considering entering this market, a PP SS spunbond machine may be a good investment. However, it is important to consider the cost of the machine and the cost of the raw materials, as well as the level of demand for nonwoven fabrics in your target market.

It is also important to consider the level of competition in the nonwoven fabric market and whether there is a need for additional production capacity. Additionally, you may want to consider the environmental impact of producing nonwoven fabrics and whether your customers prioritize sustainability.

Overall, buying a PP SS spunbond machine can be a good investment if you have carefully considered the above factors and believe China PP SS Spunbond Machine that there is a demand for nonwoven fabrics in your target market. It is important to do your research and carefully consider the costs and benefits before making a decision.

China PP SS Spunbond Machine How to Choose One

If you are interested in purchasing a PP SS spunbond machine from China, there are several factors you should consider to ensure that you choose the right one for your needs. Here are some important factors to consider:

Machine Quality: Make sure the manufacturer you choose is reliable and has a good reputation for producing high-quality machines. You can research the manufacturer’s history, check customer reviews, and ask for references from past customers.

Production Capacity: Consider the desired production capacity for your business and choose a machine that meets your requirements. Make sure the machine can produce nonwoven fabrics with the desired specifications and that it is compatible with the raw materials you plan to use.

Automation and Control: Consider the level of automation and control that you need in your production process. Some machines come with advanced automation features that can increase efficiency and reduce labor costs, while others may require more manual intervention.

After-Sales Service: Ensure that the manufacturer provides good after-sales service, including training, technical support, and spare parts. Check the manufacturer’s warranty and service agreement to make sure you are getting a machine with sufficient coverage.

Price: Finally, consider the price of the machine and make sure it fits within your budget. However, do not compromise on quality to save money in the short term, as this could result in long-term costs in terms of maintenance, downtime, and lost productivity.

Overall, choosing a PP SS spunbond machine from China requires careful consideration of these factors to ensure that you get a high-quality machine that meets your business needs and provides a good return on investment.