Posted on March 10, 2023

China High Quality Ball Bearing Introduction

A type of rolling bearing

Ball bearing is a kind of rolling bearing. The china high quality ball bearing exporter installs the spherical alloy steel ball in the middle of the inner steel ring and the outer steel ring to reduce the friction force during power transmission and improve the transmission efficiency of mechanical power by rolling. Ball bearings cannot withstand large heavy loads and are more common in light industrial machinery. Ball bearings are also called ball bearings.

product performance

The hardness of the cage is lower than that of the ball and the ring, and its material is metal (such as: medium carbon steel, aluminum alloy) or non-metal (such as: Teflon, PTEF, polymer material). Rolling bearings have less rotational friction resistance than journal bearings, so at the same speed, the temperature due to friction will be lower.

Ball bearings are generally used in equipment with low load mechanical transmission. Because the bearing area of the ball bearing is small, it is easy to cause serious mechanical damage in the case of high-speed operation. Therefore, needle bearings are often used in heavy-duty mechanical transmissions to increase the bearing area, improve mechanical transmission efficiency, and reduce Mechanical damage.

The ball bearing has changed the friction mode of the bearing, and adopts rolling friction, which more effectively reduces the friction phenomenon between the bearing surfaces, improves the service life of the fan bearing, and thus prolongs the service life of the radiator. The disadvantage is that the process is more complicated, the cost is increased, and it also brings higher working noise.

Updated on March 9, 2023

Fire monitor foam equipment valve system manufacturer

General provisions

The layout of the power supply of the Fire monitor foam equipment valve system manufacturer‘s electric tools ought to adhere to the stipulations of national requirements such as the “Code for Fire Protection in Building Design” as well as “Regulations on the Design of Power Supply and also Distribution Systems”.

In the anti-riot area of areas with surge risks, the selection and installment of electrical equipment as well as lines, and also anti-static steps for pipelines will comply with the arrangements of the national requirement “Code for Design of Electrical Equipment in Explosion and Fire Hazardous Environments”.

The layout of the electrical tools of the system shall meet the demands for the safety and security range of real-time devices, as well as will follow pertinent nationwide criteria as well as guidelines such as the “Electrical Industry Safety Regulations” as well as “Electrical Equipment Safety Rules”.

The power circulation lines of the system shall embrace flame resistant dealt with wires and also wires.

The cord laying of the system will comply with the stipulations of the nationwide standard “Code for Design of Low-Voltage Power Distribution Devices and also Circuits” as well as “Code for Design of Power Installations in Explosion and Fire Hazardous Environments”.

The lightning defense design of the system should be executed based on relevant present national standards and also regulations such as the “Code for Lightning Protection Design of Buildings”.

control

The remote screen system will have the feature of from another location managing the fire pump unit, remote screen and also relevant tools.

The system needs to embrace the affiliation control mode, and each link control system must be furnished with an operation indication signal.

The system needs to have the feature of getting emergency alarm.

The standby fire pump ought to be immediately placed into procedure when the working fire pump group breaks down.

When the remote weapon system takes on wireless control procedure, it shall meet the list below demands:

It must have the ability to regulate the throwing, straight turning as well as movement of associated valves of the fire display;

The fire control space should be able to preferentially regulate the equipment operated by the wireless controller;

The efficient control span of cordless control must be greater than 100m;

There have to be no wireless controllers with the exact same product directory within 1km, and also no cordless controllers with the very same protection code within 30m;

The wireless controller should be outfitted with a locking safety circuit.

Posted on March 8, 2023

Monorail cranes are designed for lifts in overhead or gantry cranes

Monorail cranes are designed for lifts in overhead or gantry cranes that do not require the sideways trolley movement provided by a bridge. Our company provides a variety of cranes to meet customers’ needs, such as electric bridge cranes, indoor bridge cranes, portable bridge cranes, bridge cranes, monorail cranes, etc. A reliable overhead crane is a great way to easily and quickly lift hundreds of heavy loads. We hope this article has given you a deeper understanding of what an overhead crane is. In the simplest terms, an overhead crane strikes supplies or heavy objects from one location to another in a precise manner.

Wеuѕеаnеxреrğеnсеd, qualified and licensed, complies with the strictest industrial requirements. If the load reaches 90 p.c of the crane’s rated power at a certain second, it will alert the crane operator with a slow flashing pink light. Overhead cranes are designed and produced with different lifting capacities to meet the numerous lifting needs of shoppers. Or it could be as complex as a 50 ton twin girder main operated overhead crane for proper hot dip galvanizing at the metal shop.

single-girder cranes are smaller than double-girder cranes

Generally, single-girder cranes are smaller than double-girder cranes and are often used for smaller lifting jobs. Cranes are used for handling and transferring materials in excessive environments and may handle corrosive or hazardous materials such as hot metal, chemicals and heavy metals. Overhead cranes are very important after handling heavy materials, they will move the heavy objects in different directions, greatly reducing the workload of the personnel. We back our overhead crane systems with a lifetime warranty. You should strictly adhere to regular inspections, and you will be covered by a lifetime warranty.

a tower crane has two arms: a shorter arm that carries

If you remember, a tower crane has two arms: a shorter arm that carries a counterweight that weighs the concrete block for balance, and a longer arm that carries the crane’s lifting gear. We need to help you build a basic understanding of overhead cranes and how to choose the best overhead crane manufacturer for your company’s desired cranes. LED mild bulbs can be found in a variety of color temperatures, however, due to the need for more or brighter LEDs within the bulb, the resulting hot white LED mild bulbs are more expensive, these bulbs are very light, much like the ones typically used for residential lighting Standard incandescent lamps.

Posted on March 7, 2023

How can a failing air intake hose be repaired or replaced?

If a failing air intake hose is detected, it should be repaired or replaced as soon as possible.

Here are the steps to repair or replace a failing air intake hose:

- Locate the air intake hose: The air intake hose is typically located between the air filter box and the intake manifold on the engine.

- Inspect the hose: Check the hose for any cracks, splits, or holes. If the damage is minor, it may be possible to repair the hose with duct tape or silicone sealant. However, for more serious damage, the hose should be replaced entirely.

- Remove the damaged hose: If the hose needs to be replaced, use a pair of pliers to loosen the clamps that secure the hose to the air filter box and the intake manifold. Then, carefully remove the hose from the engine.

- Install the new hose: Install the new hose by sliding it onto the air filter box and the intake manifold, and securing it with the clamps. Make sure the hose is properly seated and secured to prevent any air leaks.

- Test the engine: Start the engine and check for any signs of air leaks, such as hissing or sucking noises. If everything looks and sounds normal, the repair or replacement is complete.

Note: It is important to consult the vehicle’s owner manual for specific instructions on how to repair or replace the air intake hose on a particular make and model of vehicle.

What are the signs of a failing air intake hose?

Some common signs of a failing air intake hose include:

- Decreased engine performance: A failing air intake hose can lead to decreased acceleration or rough idling. This is because the engine is not receiving the proper amount of air, which can cause incomplete combustion.

- Illuminated check engine light: China Air intake hose supplier A damaged air intake hose can also cause the check engine light to come on. This is because the engine’s sensors are detecting that the air/fuel ratio is not within the expected range.

- Unusual engine sounds: If there is a leak in the air intake hose, it can cause hissing or sucking noises to come from the engine. This is because the engine is drawing in air from an unexpected source.

- Visual signs of damage: Cracks, splits, or holes in the air intake hose are a clear sign that it needs to be repaired or replaced.

It is important to address any issues with the air intake hose as soon as possible, as it can lead to more serious engine problems if left unaddressed.

Posted on March 7, 2023

What are the different types of rubber expansion joints?

There are several types of rubber expansion joints, including:

- Single sphere rubber expansion joint

- Double sphere rubber expansion joint

- Elbow type rubber expansion joint

- Taper rubber expansion joint

There are several types of rubber expansion joints available, including:

- Single Sphere Rubber Expansion Joint: This is the most common type of rubber expansion joint, consisting of a single rubber sphere with flanges or threaded ends. It is designed to absorb axial, lateral, and angular movements in piping systems.

- Double Sphere Rubber Expansion Joint: Similar to the single sphere joint, this type of expansion joint consists of two rubber spheres connected by a sleeve. It is better suited for systems with high axial movement and vibration.

- Elbow Type Rubber Expansion Joint: This type of expansion joint is designed to absorb angular movements in piping systems. China Rubber Expansion Joint supplier It consists of a curved rubber body with flanges or threaded ends, allowing it to absorb both lateral and angular movements.

- Taper Rubber Expansion Joint: This type of expansion joint is used in applications where the diameter of the piping changes. It consists of two rubber cones connected by a sleeve, allowing it to absorb axial and angular movements while accommodating the change in diameter.

What factors should be considered when selecting a rubber expansion joint?

Several factors should be considered when selecting a rubber expansion joint, including:

- The type of fluid or gas being conveyed: Certain chemicals and substances can react with the rubber material, which can cause the expansion joint to degrade or fail over time. It is important to ensure that the rubber material is compatible with the fluid or gas being conveyed.

- The temperature and pressure of the system: Rubber expansion joints are designed to operate within certain temperature and pressure ranges. It is important to ensure that the selected expansion joint can handle the temperature and pressure of the system.

- The amount and direction of movement expected: Different types of expansion joints are designed to absorb different types and amounts of movement, including axial, lateral, and angular movements. It is important to select an expansion joint that can accommodate the expected movement in the piping system.

- The size and length of the joint needed: The size and length of the expansion joint needed will depend on the size and layout of the piping system. It is important to select an expansion joint that can fit within the available space and accommodate the expected movement.

- The installation and maintenance requirements: Different types of expansion joints may have different installation and maintenance requirements. It is important to select an expansion joint that can be installed and maintained easily, and that is compatible with the available space and equipment.

Posted on February 22, 2023

Reasons to Use non woven supplier

There are several reasons why someone might choose to use a non-woven supplier, including:

Cost-effectiveness: Non-woven fabrics can be produced at a lower cost than woven fabrics, making them a cost-effective solution for a wide range of applications.

Versatility: Non-woven fabrics can be manufactured in a variety of weights, densities, and thicknesses, which makes them suitable for use in a wide range of products, from clothing and upholstery to medical supplies and construction materials.

Durability: Non-woven fabrics are generally strong and durable, which makes them ideal for use in products that require resistance to tearing, punctures, and other forms of damage.

Absorbency: Non-woven fabrics can be engineered to be highly absorbent, making them ideal for use in products such as diapers, medical dressings, non woven supplier and cleaning wipes.

Eco-friendliness: Many non-woven fabrics are made from recycled materials, and they can often be recycled themselves, which makes them a more sustainable choice than some other types of fabrics.

Ease of customization: Non-woven fabrics can be easily customized to meet specific needs, whether that involves adjusting the weight, thickness, or other properties of the fabric.

Overall, non-woven fabrics offer a versatile and cost-effective solution for a wide range of applications, and using a non-woven supplier can provide access to high-quality materials that meet specific needs and requirements.

How to Maintain Control in the non woven supplier Industry

Maintaining control in the non-woven supplier industry can be challenging, but there are several strategies that can be used to help ensure success.

Here are some tips for maintaining control in the non-woven supplier industry:

Establish clear goals and objectives: Develop a clear vision of what you want to achieve and establish specific, measurable goals and objectives to help you reach your targets.

Build strong relationships with customers: Build strong relationships with your customers by providing high-quality products and exceptional customer service. This will help to create customer loyalty and repeat business.

Manage your supply chain effectively: Manage your supply chain effectively to ensure that you have a reliable and consistent supply of raw materials and other resources.

Monitor your competition: Keep a close eye on your competition and stay up-to-date on industry trends and developments. This will help you to identify new opportunities and stay ahead of the competition.

Invest in technology and innovation: Invest in technology and innovation to stay ahead of the curve and continually improve your products and services.

Stay flexible and adaptable: The non-woven supplier industry is constantly changing, so it’s important to stay flexible and adaptable to new trends, regulations, and customer needs.

Develop a strong team: Build a strong team of skilled and experienced professionals who can help you to achieve your goals and maintain control in the industry.

By following these tips, you can help to maintain control in the non-woven supplier industry and achieve long-term success.

Posted on February 22, 2023

Changes in the Call Center Cubicles Office Desk Industry

The call center industry has undergone significant changes in recent years, and as a result, the call center cubicles and office desk industry has also seen some changes.

Some of the major changes include:

Ergonomic design: Call center agents typically spend long hours sitting at their desks, which can lead to discomfort and even injuries. As a result, there has been a shift towards ergonomic office furniture that is designed to promote good posture and reduce the risk of injury.

Height-adjustable desks: Another trend in the call center industry is the use of height-adjustable desks, which allow workers to switch between sitting and standing positions throughout the day. This can help improve circulation and reduce the risk of certain health problems associated with prolonged sitting.

Collaborative workspaces: Many call centers are now embracing collaborative workspaces, where agents can work together in teams to solve problems and handle customer inquiries. This has led to a greater emphasis on open-plan office designs and the use of modular furniture that can be easily reconfigured to suit different needs.

Technology integration: With the rise of digital technologies, many call centers are now using advanced software and hardware systems to manage customer interactions. call center floor plan This has led to a greater need for desks and workstations that can accommodate multiple monitors, keyboards, and other devices.

Remote work: Finally, the COVID-19 pandemic has accelerated the trend towards remote work, with many call center agents now working from home. This has led to a greater demand for lightweight, portable office furniture that can be easily transported and set up in a home environment.

Furniture Installation for Call Center Cubicles Office Desk

Installing furniture for call center cubicles and office desks can be a complex process that requires careful planning and attention to detail.

Here are some steps that can help ensure a successful installation:

Measure the space: Before ordering furniture, it’s important to accurately measure the space where the call center cubicles or desks will be installed. This will help ensure that the furniture fits properly and allows enough room for workers to move around.

Choose the right furniture: There are many different types of office furniture available, each with its own advantages and disadvantages. When selecting furniture for a call center, it’s important to consider factors such as ergonomics, durability, and ease of use.

Plan the layout: Once the furniture has been selected, it’s important to plan the layout of the space. This may involve creating a floor plan that shows where each piece of furniture will be located and how it will be arranged.

Prepare the space: Before installing the furniture, it’s important to prepare the space by removing any existing furniture, cleaning the area, and ensuring that there is adequate lighting and ventilation.

Install the furniture: The actual installation process will vary depending on the type of furniture being installed. Cubicles may require more complex installation procedures, while desks can typically be assembled using basic tools.

Test the furniture: After the furniture has been installed, it’s important to test it to ensure that it is functioning properly and meets the needs of the call center workers.

Train the workers: Finally, it’s important to train the call center workers on how to use the new furniture properly, especially if it involves new technology or ergonomic features. This can help ensure that the furniture is used correctly and can help prevent injuries or accidents.

Posted on February 21, 2023

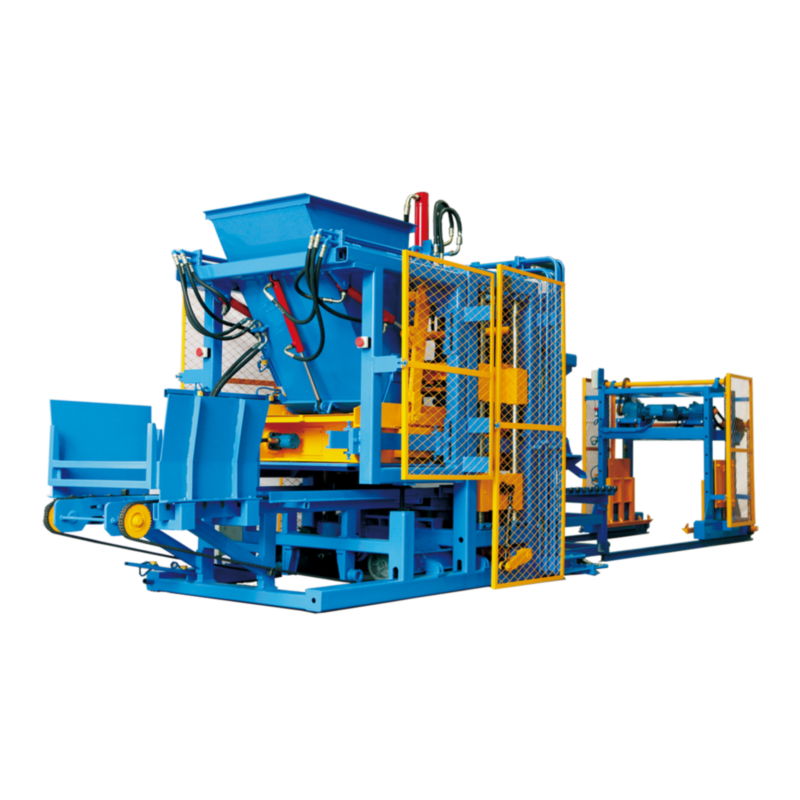

Differences Between China block machinery And India block machinery

China and India are both large and rapidly developing economies that have a significant manufacturing sector, including block machinery.

Here are some potential differences between block machinery made in China and block machinery made in India:

Manufacturing capabilities: China has a well-developed manufacturing industry with a significant focus on exports, which has allowed it to become the world’s largest producer of many industrial products. In contrast, India has a growing manufacturing sector but still lags behind China in terms of manufacturing output and export capabilities.

Quality: The quality of block machinery can vary depending on the manufacturer and the specific product. Chinese manufacturers have a reputation for producing low-cost products with varying quality levels, while Indian manufacturers tend to focus on higher quality products, although this can vary between manufacturers.

Technology and innovation: China has made significant investments in research and development and has emerged as a leader in cutting-edge technologies, China block machinery such as artificial intelligence and robotics. India, on the other hand, has a growing tech sector but is still catching up to China in terms of technology and innovation.

Price: China’s manufacturing sector is known for producing low-cost products, which can make Chinese block machinery more affordable than similar products made in India.

Market share: China dominates the global block machinery market, with a significant share of exports to various countries. In contrast, India has a smaller market share, but it is growing as the country invests in its manufacturing sector.

It’s worth noting that these are generalizations and that the quality, technology, and price of block machinery can vary widely within both countries, depending on the specific manufacturer and product.

Solid Security Glass China block machinery For Commercial, Architectural and Institutional Projects

Solid security glass is an important component of many commercial, architectural, and institutional projects, and China has a well-developed manufacturing sector that produces high-quality glass products for various applications.

Some of the key features and benefits of using Chinese block machinery to manufacture solid security glass for commercial, architectural, and institutional projects may include:

High-quality materials: Chinese manufacturers use high-quality materials, such as tempered glass, laminated glass, and bullet-resistant glass, to produce solid security glass products that are durable, long-lasting, and resistant to impacts, breakage, and forced entry.

Customized designs: Chinese manufacturers can produce solid security glass products in a wide range of sizes, shapes, and colors, and can also customize the glass to meet the specific requirements of the project, such as UV protection, sound insulation, and energy efficiency.

Advanced manufacturing technology: Chinese manufacturers use advanced manufacturing technology, such as CNC cutting, edge polishing, and automatic tempering, to produce high-quality solid security glass products with precise dimensions, smooth edges, and consistent quality.

Competitive pricing: China’s manufacturing sector is known for producing high-quality products at a competitive price point, making solid security glass products from China an attractive option for projects with a tight budget.

Large production capacity: China has a large production capacity for glass products, which allows manufacturers to quickly produce and deliver large quantities of solid security glass products to meet the demands of commercial, architectural, and institutional projects.

Overall, using solid security glass products manufactured by Chinese block machinery can provide a cost-effective and high-quality solution for commercial, architectural, and institutional projects that require durable and secure glass products.

Posted on February 21, 2023

Build a Concrete Block Making Machine – Make Money With Concrete Blocks

Building a concrete block making machine can be a lucrative business idea if done correctly.

Here are some steps to help you get started:

Research and Plan: Before you begin building your machine, research the different types of concrete blocks and their uses. Determine the size and type of machine you want to build and create a detailed plan of the design.

Gather Materials: Purchase or collect all the materials you will need to build your machine. This includes steel for the frame, motors, hydraulic pumps, and other components necessary to operate the machine.

Build the Frame: Construct the frame of the machine using steel beams and angle iron. The frame should be sturdy and able to support the weight of the components.

Install the Motors and Hydraulic Pumps: Mount the motors and hydraulic pumps to the frame. These components are responsible for powering the machine and allowing it to produce concrete blocks.

Build the Block Molds: Construct the block molds using plywood or steel. The molds should be the appropriate size and shape for the type of block you want to produce.

Connect the Components: Connect the motors and hydraulic pumps to the block molds using hoses and other connectors. This will allow the machine to produce concrete blocks when it is turned on.

Test the Machine: Test the machine to ensure that it is producing concrete blocks correctly. Make any necessary adjustments to the components or settings to optimize the production process.

Once you have built your concrete block making machine, you can start producing blocks and selling them to construction companies, contractors, or individuals. You can also consider expanding your business by offering customized blocks or by providing block-making services to customers. With the right planning and execution, building a concrete block making machine can be a profitable venture.

Make concrete blocks making machines For Profits – A Business With A Great Foundation

Making concrete blocks using machines can be a profitable business venture with a solid foundation.

Here are some steps to help you get started:

Determine the Market: Research the demand for concrete blocks in your area. Identify potential customers, including contractors, construction companies, and builders, and analyze their needs and preferences.

Design Your Machines: Develop a design for your concrete block making machines. Consider factors such as production capacity, block size and shape, concrete blocks making machines and automation levels. You can either purchase a pre-designed machine or create a custom machine to suit your specific requirements.

Gather Materials and Equipment: Purchase or collect all the materials and equipment necessary to build your machines, including steel, hydraulic pumps, motors, and block molds. You’ll also need a space to operate the machines, such as a warehouse or factory.

Build the Machines: Construct the machines according to your design, making sure they are sturdy, durable, and efficient. Test the machines thoroughly to ensure they are producing high-quality concrete blocks.

Market Your Business: Promote your concrete block making business to potential customers. Use social media, online marketing, and local advertising to increase your visibility and attract clients.

Deliver Your Product: Begin producing and delivering your concrete blocks to your customers. Ensure you have a consistent supply of raw materials and that your machines are maintained and repaired regularly to avoid downtime.

Expand Your Business: As your business grows, consider expanding your operations by adding more machines, diversifying your product range, or expanding your customer base.

In summary, building a concrete block making machine for profits is an excellent business idea with a great foundation. By designing and building high-quality machines and marketing your business effectively, you can establish yourself as a reliable supplier of concrete blocks in your local market and beyond.

Posted on February 21, 2023

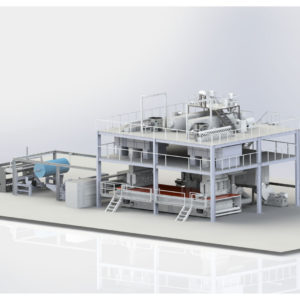

Should You Buy a PP SS Spunbond Machine?

As an AI language model, I cannot provide a definitive answer as to whether you should buy a PP SS spunbond machine, as it depends on various factors such as your business goals, budget, and market demand. However, I can provide you with some information that may help you make an informed decision.

PP SS spunbond machines are used in the production of nonwoven fabrics, which are used in a variety of applications such as medical supplies, protective clothing, and home textiles. These machines use polypropylene (PP) as the main raw material, and the SS in the name stands for “spunbond + spunbond,” referring to the production process that involves spinning the fibers and bonding them together.

If you are in the business of producing nonwoven fabrics or are considering entering this market, a PP SS spunbond machine may be a good investment. However, it is important to consider the cost of the machine and the cost of the raw materials, as well as the level of demand for nonwoven fabrics in your target market.

It is also important to consider the level of competition in the nonwoven fabric market and whether there is a need for additional production capacity. Additionally, you may want to consider the environmental impact of producing nonwoven fabrics and whether your customers prioritize sustainability.

Overall, buying a PP SS spunbond machine can be a good investment if you have carefully considered the above factors and believe China PP SS Spunbond Machine that there is a demand for nonwoven fabrics in your target market. It is important to do your research and carefully consider the costs and benefits before making a decision.

China PP SS Spunbond Machine How to Choose One

If you are interested in purchasing a PP SS spunbond machine from China, there are several factors you should consider to ensure that you choose the right one for your needs. Here are some important factors to consider:

Machine Quality: Make sure the manufacturer you choose is reliable and has a good reputation for producing high-quality machines. You can research the manufacturer’s history, check customer reviews, and ask for references from past customers.

Production Capacity: Consider the desired production capacity for your business and choose a machine that meets your requirements. Make sure the machine can produce nonwoven fabrics with the desired specifications and that it is compatible with the raw materials you plan to use.

Automation and Control: Consider the level of automation and control that you need in your production process. Some machines come with advanced automation features that can increase efficiency and reduce labor costs, while others may require more manual intervention.

After-Sales Service: Ensure that the manufacturer provides good after-sales service, including training, technical support, and spare parts. Check the manufacturer’s warranty and service agreement to make sure you are getting a machine with sufficient coverage.

Price: Finally, consider the price of the machine and make sure it fits within your budget. However, do not compromise on quality to save money in the short term, as this could result in long-term costs in terms of maintenance, downtime, and lost productivity.

Overall, choosing a PP SS spunbond machine from China requires careful consideration of these factors to ensure that you get a high-quality machine that meets your business needs and provides a good return on investment.