Posted on January 6, 2024

Low Cement Castable: The Next Evolution in High-Performance Refractories

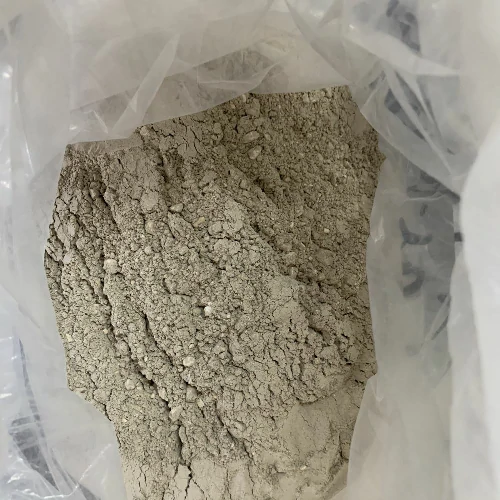

Low cement castable refractories represent a significant innovation in the realm of refractory materials, offering exceptional strength, thermal shock resistance, and superior performance in high-temperature environments. Engineered with reduced cement content, these castables provide remarkable durability and stability in diverse industrial applications where extreme heat and harsh conditions prevail.

Understanding Low Cement Castable Refractories

- Composition: Low cement castables feature a reduced proportion of cement compared to conventional castables. They primarily consist of high-quality refractory aggregates, fine powders, and carefully selected bonding agents.

- Advanced Binders: Sophisticated binders, such as ultrafine particles and reactive alumina additives, enhance particle packing and reduce porosity, contributing to improved mechanical properties.

Key Features and Benefits

- Enhanced Strength: Reduced cement content results in higher strength and density, offering superior mechanical properties, abrasion resistance, and structural integrity in high-temperature environments.

- Thermal Shock Resistance: These castables exhibit excellent resistance to thermal shock, maintaining stability and performance even in rapid temperature variations or severe thermal cycling.

- Lower Porosity: The decreased cement content leads to reduced porosity, minimizing gas permeability and enhancing resistance to slag penetration and chemical attack.

Applications in Various Industries

- Steel and Metal Industries: Low cement castables find use in steelmaking, ladles, tundishes, and other high-temperature vessels, providing superior lining solutions for improved performance and durability.

- Incinerators and Petrochemical Plants: They serve as linings in rotary kilns, boilers, and reactors, offering exceptional thermal insulation and chemical resistance in harsh environments.

- Cement and Ceramics Manufacturing: These castables are utilized in cement kilns, preheaters, and ceramic kilns, ensuring reliability and longevity in high-temperature production processes.

Benefits for Industrial Applications

- Optimized Performance: The advanced formulation of low cement castables enhances refractory performance, reducing downtime and maintenance costs in industrial operations.

- Energy Efficiency: Their superior thermal conductivity and insulation properties contribute to energy savings by reducing heat loss and improving furnace efficiency.

Considerations and Installation

- Material Selection: Tailoring the composition of low cement castables to suit specific temperature ranges and environmental conditions is crucial for optimal performance in different industrial settings.

- Installation Techniques: These castables are installed by casting, gunning, or shotcreting methods, ensuring proper placement, consolidation, and curing to achieve desired thermal efficiency and stability.

Low cement castable refractories represent a significant advancement in high-performance refractory materials, offering exceptional strength, thermal shock resistance, and durability in extreme heat applications. Their ability to withstand severe conditions, coupled with improved mechanical properties and reduced porosity, makes them indispensable in steel, petrochemical, cement, and ceramics industries. Understanding their composition and application benefits empowers industries to leverage these advanced castables effectively, ensuring enhanced performance, extended service life, and reliability in high-temperature environments.